ElectroStatic Separators for E-waste Recycling in Australia

By Gordon Kerr | 23 July 2025

Australian electronic waste recycler Sircel Ltd has purchased two ElectroStatic Separators from Bunting Magnetics. The orders were placed after controlled test work undertaken at Bunting’s UK-based Customer Experience Centre. The ElectroStatic Separators have been integrated into Sircel’s e-waste processing and recycling plant.

Bunting Magnetics is one of the world’s leading designers and manufacturers of magnetic separators, eddy current separators, metal detectors and electrostatic separators, with globally located manufacturing facilities.

Sircel Ltd is an innovative recycling company with a mission to eradicate electronic waste. Based in Australia, Sircel has pioneered an ethical and sustainable e-waste recycling solution, including the development of a world-leading recycling process that diverts up to 100% of end-of-life electronics from landfill.

Globally, only around 20% of e-waste is formally recycled. A large proportion of electronic waste generated by industrialised countries is exported for processing, often to developing countries, where there are less stringent environmental regulations, but the actual recycling capabilities are poor.

In 2017, Sircel’s CEO, Anthony Karam, was inspired to take action after seeing enormous e-waste landfill dumps in Africa. His passion and vision to address the e-waste problem led to establishing six operational recycling sites around Australia, providing a solution to end-of-life technology.

The separation and recovery of metal from e-waste is a key stage in the successful recycling process. Sircel contacted Bunting for advice and sent material to the UK Customer Experience Centre for testing on a range of metal separation equipment including the ElectroStatic Separator.

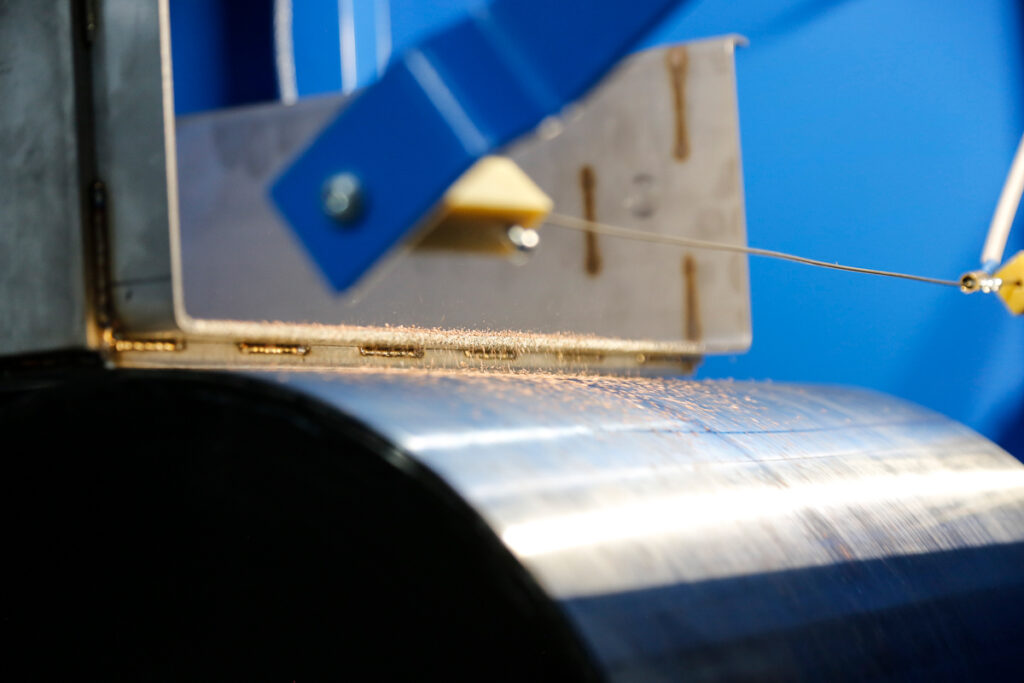

ElectroStatic Separators provide the only existing mechanical separation method for a number of recycling applications. An ElectroStatic Separator exploits the difference in electrical conductivity between various materials in a feed material to produce a separation. The ability to produce a separation depends on a number of key material characteristics including a particle’s size and conductivity.

In many applications, commonly where the particle size range is fine, the ElectroStatic Separator is the only technology able to execute separation (e.g. -2mm granulated cable scrap).

In operation, ElectroStatic technology utilises the difference in conductivity between insulators (plastics) and conductors (copper and aluminium) to obtain a separation on an earthed roll. The insulators are pinned to the earthed roll via an image force whilst the conductors lose their charge and are thrown from the roll by the centrifugal force generated. Separations can also be achieved between particles of different conductivity (e.g. copper and aluminium).

In the Sircel process, the 1000mm wide ElectroStatic Separators, with fully integrated controls, are recovering and concentrating the fine copper. . Depending on the grade, condition and market conditions, copper prices range from £4,300 to £7,000 per tonne in the UK. Maximising the recovery and purity of the copper present in electronic waste is important for the economic viability of the process. The ElectroStatic Separator is particularly adept at recovering the very fine copper wire, which is often lost to waste.

“Our applications team worked very closely with the Sircel engineers to understand the process and separation objectives,” explained Bradley Greenwood, Bunting’s European Head of Sales. “Through extensive testing on our laboratory-scale ElectroStatic Separator, it was possible to confirm the level of copper recovery and purity. Collaboration on complex projects such as these is vital to ensure the end separation objectives are achieved to improve global recycling rates.”

Contact us to discuss how we can help you find the best separator for your application.