Plastic Industry

Removing Metal contamination from Plastic

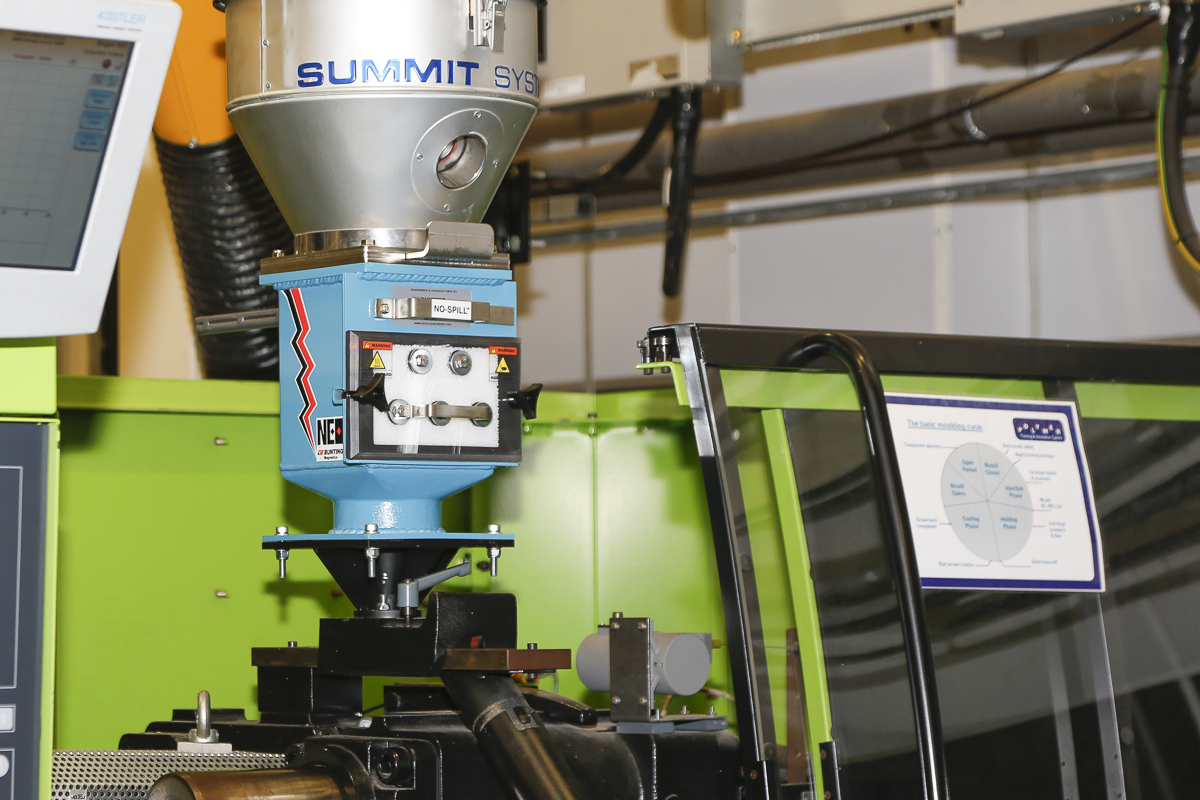

- Drawer Filter Magnets – the plastics industry standard for magnetic separation, featuring strong Neodymium Tube Magnets to capture both large and small ferrous metals. Commonly located above injection moulding machines;

- Plate Magnets – ideal for removing larger tramp metal. Ferrite and Neodymium Plate Magnets are installed suspended over conveyors and in chutes;

- Metal Detectors – with designs for free-fall applications or mounted on conveyors, Bunting’s extensive range of Metal Detectors identify and remove both ferrous and non-ferrous tramp metal;

- Eddy Current Separators – using high-powered magnetic rotors to dynamically eject non-ferrous metals (e.g. aluminium) from shredded or granulated plastic waste;

- Stainless Steel Separator – the ultra-strong magnetic separator that removes weakly magnetic metals (such as stainless steel);

- ElectroStatic Separators - The revolutionary electrostatic separator provides the only known method of separating small conductive metals;

Technical Articles

- Metal Separator Locations in a Plastics Plant

- Metal Separation from Plastic Flake

- EcoVyn Reduce Plastic Waste by 94% with Bunting

Plastic Industry Products

Magnetic Separators

Drawer Filter Magnets

The magnetic separator working in plastics plants globally, removing ferrous metal from plastic flake, plastic beads, and shredded plastic waste.

Drawer Filter Magnets

Plate Magnets

Tube & Grid Magnets

Drum Magnets - Permanent

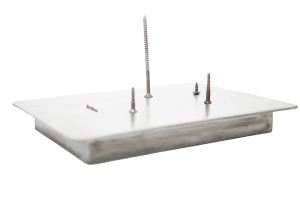

Plate Magnets

Located in chutes and suspended above conveyors to capture and securely hold tramp ferrous metal such as nuts, bolts, screws, and nails.

Drum Magnets

Tube & Grid Magnets

High-strength neodymium rare earth tube magnets, commonly arranged in a grid, trap and securely hold small and large tramp ferrous metal.

Drum Magnets - Permanent

Both low and high-intensity Drum Magnets provide continuous and automatic removal of coarse and small magnetic particles.

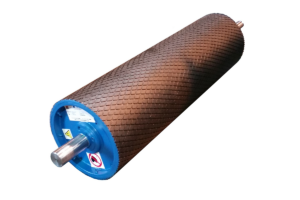

Pulley Magnets

Pulley Magnets replace conveyor head pulleys and automatically remove tramp ferrous metal from conveyed plastics, raw materials, and plastic waste.

Eddy Current Separators

Separate large and small non-ferrous metals, such as aluminium, from shredded plastic waste with designs to suit specific applications.

Electrostatic Separators

A new generation of separator, enabling the removal of ultra-fine non-ferrous metals from shredded plastic waste.

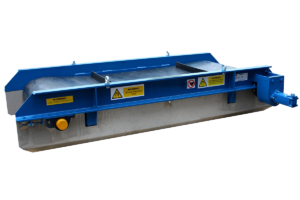

Overband Magnets

Overband magnets, suspended over conveyors, separate frequently occurring disruptive tramp ferrous metal and are available as permanent and electromagnetic designs.

Suspension Magnets

Suspension Magnets, suspended above conveyors, separate occasional tramp ferrous metal and are available in permanent and electromagnetic versions.

Stainless Steel Separators

The ultra-high-intensity magnetic separator removes even the weakest magnetic contamination from plastic raw materials and plastic waste.

Pulley Magnets

Eddy Current Separators

Electrostatic Separators

Overband Magnets

Suspension Magnets

Stainless Steel Separator

Metal Detectors

Free-Fall Metal Detectors

As dry, free-flowing plastic and shredded plastic waste falls through the metal detector, any identified tramp metal gets automatically rejected.

Conveyor Metal Detectors

High-sensitivity metal detectors mounted around a conveyor to locate any metal contaminant present in the plastic profile, bottle, or product.

Free-Fall Metal Detector

Conveyor Metal Detectors

As dry, free-flowing plastic and shredded plastic waste falls through the metal detector, any identified tramp metal gets automatically rejected.

High-sensitivity metal detectors mounted around a conveyor to locate any metal contaminant present in the plastic profile, bottle, or product.

Metal Detectors

Free-Fall Metal Detectors

Conveyor Metal Detectors

Magnetic Separators for Plastics

In the production of primary plastic products, metal contamination damages processing equipment such as injection moulding machines and extruders and causes finished product defects. The equipment damage is costly in terms of repair costs and production downtime. The type of metal contamination ranges from a rogue screw or bolt to fine shards (from process plant wear).

Magnetic Separators for Plastic Waste

A greater proportion and range of metal contamination occurs in plastic waste. Larger tramp metal, such as a spanner, can prove devastating to a shredder or granulator. Non-ferrous metals, such as aluminium, can significant reduce the value of the end recycled plastic material. Ensuring the recycled plastic is metal-free has never been more important as recycled material becomes an increasing proportion of the raw material feed.

Metal Detectors for Plastics and Plastic Waste

Metal Detectors work alongside magnetic separators to identify and remove metal contamination during the plastic product or plastic waste recycling process. Highly sensitive metal detectors check final product purity prior and recycled plastic profiles prior to shredding.