Mining and Mineral Processing

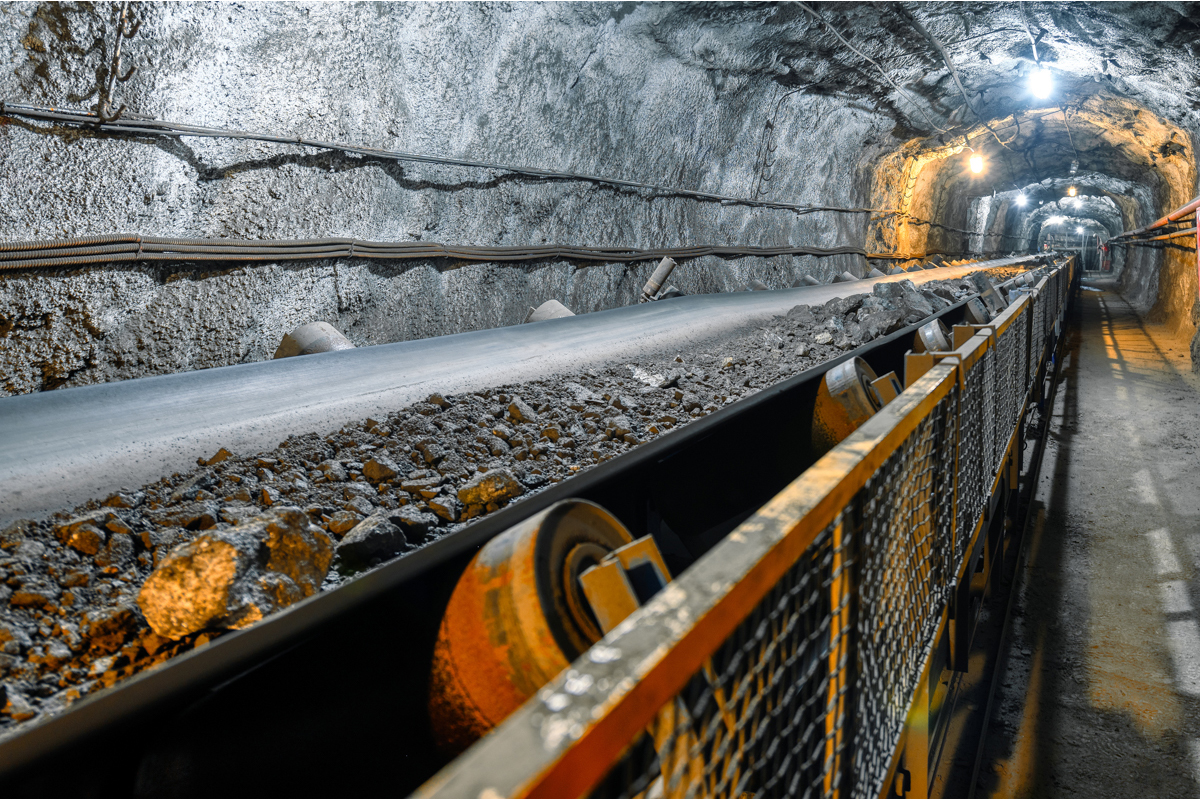

Purifying and concentrating minerals and removing tramp metal in Mining and Mineral Processing

- Electro and Permanent Overband Magnets – suspended over conveyed mined rock to lift and remove tramp metal for crusher and screen protection;

- Pulley Magnets –replace head pulleys for enhanced tramp metal removal

- Drum Magnets – ideal when the magnetic force requirement is higher, especially when separating magnetically susceptible ores;

- Metal Detectors – the final stage of protection, identifying potentially damaging ferrous and non-ferrous metals such as digger teeth;

- Rare Earth Roll Magnetic Separators – ultra high magnetic fields generated by Neodymium Rare Earth magnets for separating weakly and para-magnetic minerals from silica sand, feldspar and other non-metallic minerals in a dry state;

- Induced Roll Magnetic Separators - an electromagnetic version of the Rare Earth Roll Separator commonly used for more arduous applications such as abrasives and refractory minerals;

- Magnetic Disc Separators (MDS) – a specialist high-intensity magnetic separator for processing materials including beach sands and Coltan;

- Electro Magnetic Filters – electromagnetic high-intensity system for removing weak and fine magnetic particles from mineral slurries (e.g. silica sand, feldspar, clay) and ceramics slips and glazes;

Technical articles

Bunting’s Customer Experience Centre (Redditch, UK) has one of the world’s most complete laboratories for high-intensity magnetic separation for the mineral processing and mining industry. Customers are invited to contact us to arrange controlled tests to determine separation capabilities. Find out more on:

Click below to see how Bunting's Magnetic Disc Separator works in a typical Mining and Mineral Processing industry application

Mining and Mineral Processing Industry Products

Rare Earth Roll

Induced Roll Separator

Magnetic Disc Separator

Drum Magnets - Permanent

Electro Magnetic Filters

Overband Magnets

Suspension Magnets

Pulley Magnets

Rare Earth Roll

High-intensity magnetic separators for dry materials and used to remove free iron from dry raw materials (e.g feldspar and silica sand) and spray-dried ceramic powders.

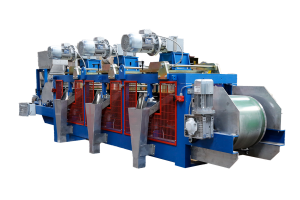

Induced Roll Separator

Electromagnetic high-intensity magnetic separator used for dry mineral purification of non-metallic minerals such as feldspar and silica sand.

Wet Drum

Metal Detectors

Magnetic Disc Separator

The Magnetic Disc Separator (MDS) is a sorting system equipped with up to three independently working discs which generate magnetic field strengths up to 14,000 gauss. The high magnetic forces that the MDS generates are able to extract paramagnetic particles from a free-flowing, dry product stream (100μm – 1.5mm).

Drum Magnets - Permanent

Both low and high-intensity and permanent and electro Drum Magnets for continuous removal of free iron and magnetic minerals. The robust nature of the Drum Magnet makes them ideal for heavier duty applications.

Electro Magnetic Filters

The Electro Magnetic Filter produces a high-intensity magnetic field (up to 40,000 Gauss) to separate fine iron and paramagnetic minerals from mineral slurries such as kaolin, ball clay, and silica sand.

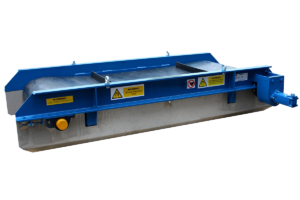

Overband Magnets

Overband magnets are suspended over conveyors to separate frequently-occurring disruptive tramp ferrous metal and are available as permanent and electromagnetic designs. The self-cleaning belt enables the automatic discharge of separated metal into a collection area. Bunting provides bespoke designs for high-capacity applications such as coal and bulk material handling terminals.

Suspension Magnets

Suspension Magnets sit above conveyors to separate occasional tramp ferrous metal and are available in permanent and electromagnetic versions. The captured metal is held securely on the face of the Suspension Magnet until manually cleaned.

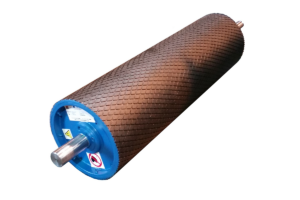

Pulley Magnets

The Magnetic Head Pulley replaces the standard head pulley of a conveyor to provide continuous separation of disruptive tramp ferrous metal from a conveyed product, it is simple to install and requires minimal maintenance.

Wet Drums

The Wet Drum Magnetic Separator recovers magnetite and ferro-silicon in dense media plants and is also used in iron ore beneficiation. Magnetite recovery commonly occurs in coal washing plants.

Metal Detectors

A wide range of specialist industrial metal detectors, designed for mining and mineral processing operations, providing protection against tramp metal damage to screens, crushers and conveyors.

Magnetic Separators for Mining and Mineral Processing

For decades, mining and mineral processing companies have turned to Bunting’s range of magnetic separators and metal detectors for high-specification separation.

High Intensity Magnetic Separators for Mineral Processing

High-intensity magnetic separators provide the ultimate solution for the removal of fine free iron and paramagnetic minerals. High-intensity magnetic separators such as the Rare Earth Roll Separator and Induced Magnetic Roll enable non-metallic mineral processors to remove paramagnetic minerals to produce high quality, high-purity mineral products.

Heavy-duty Magnetic Separators for Mining

High-volume mining operations require heavy-duty magnetic separators and metal detectors. Bunting provides both standard models and bespoke designs of electro and permanent Overband Magnets, as well as specialist mining-specific metal detectors. In addition, Bunting provides Wet Drum Magnetic Separators for dense-media plants.