Steelworks and Slag Processing

Removing Metal Contamination from Steelworks and Slag Processing

- The most common method of recovering steel is when crushed slag is fed onto the surface of a heavy-duty Electro or Permanent drum magnet. Magnetic material is attracted to the strong magnetic field of the stationary magnetic element inside the drum and then moved and deposited underneath and away from the slag through the motion of the rotating outer shell. The outer shell is commonly manufactured out of manganese steel or has an easily replaceable wear wrap;

- When it is not possible to install a Drum Magnet, a conveyor’s head pulley is replaced with a Pulley Magnet. Ferrous metal is attracted to the magnetic field and deposited underneath the conveyor and away from the non-magnetic slag;

- A third option involves suspending a Permanent Overband or Suspension Magnet (i.e. self-clean or manual clean) across or over a conveyor. Metal is lifted off the conveyor belt and either held on the magnet face or automatically discharged. Commonly Overband Magnets are used to remove large tramp metal that could damage the crusher;

Steelworks and Slag Processing Industry Products

Electro Drum Magnets

Heavy-duty large diameter Electro Drum Magnets recover ferrous metal from incineration ash, steel slag and automobile shredded scrap.

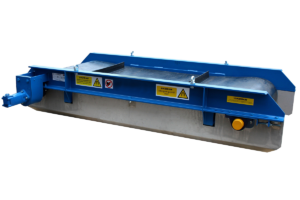

Overband Magnets

Overband magnets, suspended over conveyors, recover ferrous metal from crushed slag and are available as permanent and electromagnetic designs.

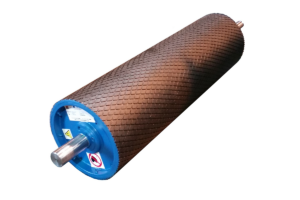

Magnetic Head Pulleys

The Magnetic Head Pulley replaces the standard head pulley of a conveyor to provide continuous separation of ferrous metals from conveyed products.

Drum Magnets - Electro

Overband Magnets

Magnetic Head Pulleys

Magnetic Separators for Steelworks and Slag Processing

Steel slag is produced during the steel making process where, after air cooling, a dense rock material is processed and sized into specific products suitable for diverse applications. These include construction aggregates, rail ballast, agricultural soil amendment, in the manufacture of cement and as an environmental remediation material. The durability and surface properties of steel slag also make it an ideal material for use in asphalt where high grip surfacing is required for skid resistance.

The slag produced during the steel manufacturing process contains high amounts of valuable ferrous metals. The slag is passed through a process of crushing (primary and secondary) and screening to liberate the metal from the gangue. This ferrous metal is then recovered using heavy duty magnetic separators of various designs including Electro Drum Magnets and large Electro Overband Magnets with reinforced belts.