Power Stations

Removing Metal Contamination from Power Stations

- Suspending a self-cleaning Overband Magnet or manual-clean Suspension Magnet across or over a conveyor. Metal is lifted off the conveyor belt and either held on the magnet face or automatically discharged.

- Replacing a conveyor’s head pulley with a Pulley Magnet. Ferrous tramp metal is attracted to the magnetic field and deposited underneath the conveyor out of the product stream.

- Feeding material onto a heavy-duty Drum Magnet either directly or via a vibratory feeder. Magnetic material is attracted to the strong magnetic field and deposited underneath and away from the product;

- Eddy Current Separators physically and continuously eject non-ferrous metals (eg. out of biomass and RDF to remove potentially problematic aluminium and other non-ferrous metals entering the furnace;

- Metal Detectors are commonly used after or even before Magnetic Separators to detect tramp metal. Used in combination, Magnetic Separators and Metal Detectors provide optimum protection. This results in less production downtime and reduced maintenance and repair costs.

Technical Articles

Power Station Industry Products

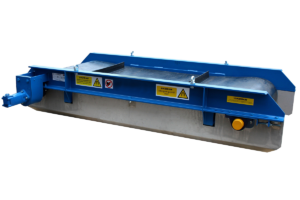

Overband Magnets

Overband magnets are suspended over conveyors to remove problematic tramp ferrous metals from coal, and recover ferrous metals (e.g. cans) from RDF. Many designs for power stations are bespoke due to conveyor speed and size, burden depths, and ferrous metal specification.

Suspension Magnets

Suspension Magnets, suspended over conveyors, separate occasional ferrous metal and protect equipment such as shredders. Available in permanent and electromagnetic versions.

Drum Magnets - Electro

Heavy-duty large diameter Electro Drum magnets are often placed at the end of conveyor lines to extract and recover larger-sized ferrous metals from high-volume material flows.

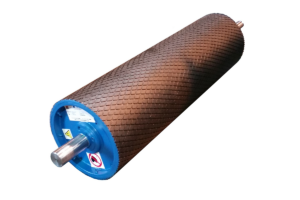

Magnetic Head Pulleys

The Magnetic Head Pulley replaces the standard head pulley of a conveyor to provide continuous separation of ferrous metals from conveyed products. Often used in conjunction with a suspended magnetic separator when the burden depth is particularly deep.

Eddy Current Separators for Non-Ferrous metals

Separate and recover large and small non-ferrous metals from RDF including materials such as aluminium beverage cans.

Conveyor Metal Detectors

High-sensitivity metal detectors mounted around a conveyor to locate any metal contaminant present in the transported coal or RDF.

Overband Magnets

Suspension Magnet

Drum Magnets - Electro

Magnetic Head Pulleys

Eddy Current Separators for Non-Ferrous metals

Conveyor Metal Detectors

Magnetic Separators for Power Stations and Energy-from-Waste Plants

Magnetic Separators and Metal Detectors are key equipment in any power station, removing problematic and damaging tramp metal from conveyed fuel (including biomass, coal, refuse, wood, etc). Successful removal of such large tramp metal protects against costly damage of crushers and other processing machinery and potential plant downtime for emergency repairs. For larger bulk handling terminals (sending and receiving coal, wood, biomass, etc), Bunting design large, bespoke Electro Overband Magnets.

Metal Detectors for Power Stations and Energy-from-Waste Plants

Metal Detectors feature in locations where there is a high risk of equipment damage or fire. Positioned around a conveyor, the high-sensitivity metal detectors identify any metal contamination and either stop the process for removal or automatically reject the contaminated material.