Food Processing

Removing and detecting metal contamination in food

- Removing ferrous metal (fine and coarse) from liquids, fluids and slurries with Liquid Pipeline Magnetic Separators fitted with high-intensity Neodymium Rare Earth Tube Magnets;

- Cleansing powders and granules of iron contamination with both standard strength Ferrite and high-intensity Neodymium Rare Earth Tube and Grid Magnets, Plate Magnets, Inline Magnets, Bullet Magnets and Drum Magnets. The application and installation dictate the optimum design of magnetic separator;

- Detecting ferrous and non-ferrous metals during the production process or once packaged prior to final despatch with a wide range of gravity-fed and conveyor mounted Metal Detectors;

Food Processing Industry Products

Magnetic Separators

Tube & Grid Magnets

Tube Magnets (also referred to as Magnetic Rods, Cartridge Magnets and Grid Magnets) remove problematic ferrous metal from dry processed foodstuffs, preventing damage to processing equipment, and protecting product quality.

Tube & Grid Magnets

Drawer Filter Magnets

Liquid Pipeline Magnets

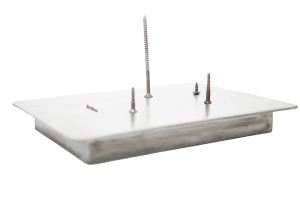

Plate Magnets

Tube Magnets (Magnetic Rods and Cartridge Magnets) and Grid Magnets remove problematic ferrous metal from dry processed foodstuffs, preventing damage to processing equipment, and protecting product quality.

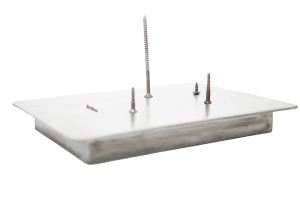

Drawer Filter Magnets are equipped with powerful Tube Magnets to capture ferrous particles from dry foodstuffs in gravity flow or free-fall applications. This prevents damage to processing equipment and protects product quality.

Liquid Pipeline Magnetic Separators or Traps extract fine iron from liquids and slurries conveyed in a pipeline. Tube Magnets, positioned in the material flow, attract and then securely hold magnetic metal contamination.

Permanent Plate Magnets remove tramp ferrous metal from conveyed or gravity-fed product flows, with installation above conveyed foodstuffs or in chutes, with tramp ferrous metal captured and held prior to manual removal.

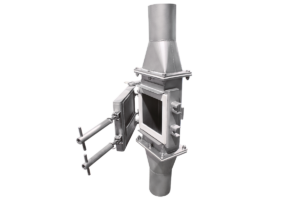

Inline Magnets

Bullet Magnets

Drum Magnets - Permanent

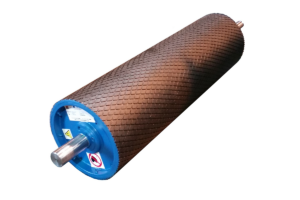

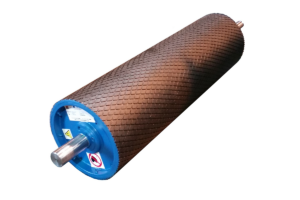

Magnetic Head Pulley

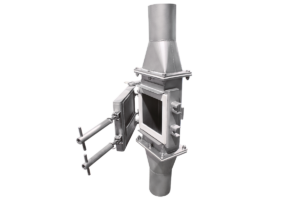

Inline Magnets, installed in gravity-fed and pneumatic pipelines, feature a powerful Plate Magnet fitted on one side of the body, which captures and securely retains rogue tramp ferrous metal.

Bullet Magnets feature a centrally located, powerful magnetic cone, which captures and securely holds ferrous metal particles present in dry, free-flowing materials, such as grains and flour, in vertical gravity-fed installations.

Permanent Drum Magnets automatically and continuously remove both weak and strong magnetic contaminants from dry granular foodstuffs, and are ideally suited for high-volume applications.

A Magnetic Head Pulley replaces the standard head pulley of a conveyor and features a deep magnetic field that continuously separates tramp ferrous metal from dry conveyed foodstuffs.

Food Processing Industry Products

Magnetic Separators

Tube & Grid Magnets

Drawer Filter Magnets

Liquid Pipeline Magnets

Plate Magnets

Drawer Filter Magnets

Drawer Filter Magnets are equipped with powerful Tube Magnets to capture ferrous particles from dry foodstuffs in gravity flow or free-fall applications. This prevents damage to processing equipment and protects product quality.

Inline Magnets

Bullet Magnet

Drum Magnets - Permanent

Magnetic Pulley Magnets

Suspension Magnets

X-Ray Inspection Systems

Liquid Pipeline Magnets

Liquid Pipeline Magnetic Separators or Traps extract fine iron from liquids and slurries conveyed in a pipeline. Tube Magnets, positioned in the material flow, attract and then securely hold magnetic metal contamination.

Plate Magnets

Permanent Plate Magnets remove tramp ferrous metal from conveyed or gravity-fed product flows, with installation above conveyed foodstuffs or in chutes, with tramp ferrous metal captured and held prior to manual removal.

Inline Magnets

Inline Magnets, installed in gravity-fed and pneumatic pipelines, feature a powerful Plate Magnet fitted on one side of the body, which captures and securely retains rogue tramp ferrous metal.

Bullet Magnets

Bullet Magnets feature a centrally located, powerful magnetic cone, which captures and securely holds ferrous metal particles present in dry, free-flowing materials, such as grains and flour, in vertical gravity-fed installations.

Drum Magnets - Permanent

Permanent Drum Magnets automatically and continuously remove both weak and strong magnetic contaminants from dry granular foodstuffs, and are ideally suited for high-volume applications.

Magnetic Pulley Magnets

A Magnetic Head Pulley replaces the standard head pulley of a conveyor and features a deep magnetic field that continuously separates tramp ferrous metal from dry conveyed foodstuffs.

Suspension Magnets

Suspension Magnets sit over conveyors and use either a permanent or electromagnetic field to lift and securely hold larger tramp ferrous metal present in foodstuffs, especially early in the process checking delivered products.

X-Ray Inspection Systems

The inclusion of an X-Ray inspection system in a food or pharmaceutical manufacturing process ensures the quality and safety of the final packaged product. The X-Ray easySCOPE detects both metallic and non-metallic impurities, including metal, glass, stone and plastic.

Metal Detectors

Belt Conveyor Metal Detectors

High sensitivity Metal Detectors detect, and can reject, metal contaminated conveyed food products, whether loose or packed. Such food metal detectors ensure consumer-bound food products are metal-free.

Free Fall Metal Detector

Gravity free-fall style metal separators and metal detectors detect and automatically reject small ferrous and non-ferrous metal contaminants from dry, free-flowing foodstuffs, with many installed with a Drawer Filter Magnet.

Pipeline Metal Detectors

Installed in pipelines for vacuum, suction, and pneumatic conveying, the pipeline metal detector identifies and removes metal contamination present in a wide range of wet and dry foods including powders, grains, liquids, and pastes.

Meat Metal Detectors

The meatLINE range of meat Metal Detectors detect and remove metal when handling processed meat slurries, minced meat, and meat pastes used in pastry products. The metal detectors include vacuum filters.

Belt Conveyor Metal Detectors

Free Fall Metal Detectors

Pipeline Metal Detectors

Meat Metal Detectors

High sensitivity Metal Detectors detect, and can reject, metal contaminated conveyed food products, whether loose or packed. Such food metal detectors ensure consumer-bound food products are metal-free.

Gravity free-fall style metal separators and metal detectors detect and automatically reject small ferrous and non-ferrous metal contaminants from dry, free-flowing foodstuffs, with many installed with a Drawer Filter Magnet.

Installed in pipelines for vacuum, suction, and pneumatic conveying, the pipeline metal detector identifies and removes metal contamination present in a wide range of wet and dry foods including powders, grains, liquids, and pastes.

The meatLINE range of meat Metal Detectors detect and remove metal when handling processed meat slurries, minced meat, and meat pastes used in pastry products. The metal detectors include vacuum filters.

Metal Detectors

Belt Conveyor Metal Detector

Free Fall Metal Detectors

Pipeline Metal Detectors

Meat Metal Detectors

Magnetic Separators in Food Processing

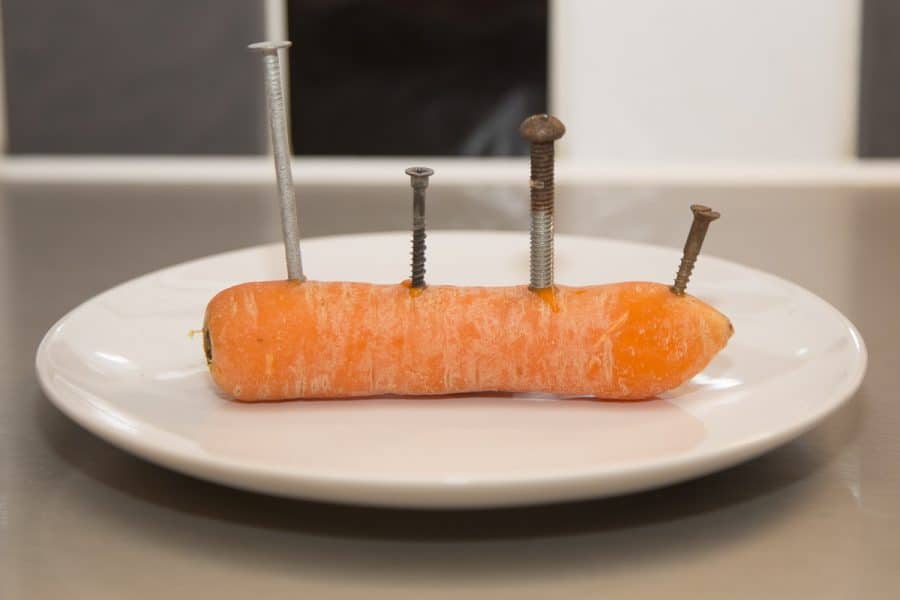

The diverse range of magnetic separators used in the food processing enables the capture of small and large tramp ferrous metal, such as nails, screws, and rust. Most magnetic separators used in food manufacturing use ultra-strong Neodymium rare earth magnets, which capture weakly magnetic contamination such as abraded stainless-steel.

Metal Detectors in Food Processing

Although the most common location for Metal Detectors in a food processing plant is prior to and after packing or containerisation, the technology also features at many earlier stages within the process. Metal Detectors play a key role in most food processing operations, using high-sensitivity coils to detect a wide range of metal contamination. Many metal detectors include automated reject systems to eject contaminated food products, whether loose or in packaging.

Total Metal Separation for the Food Industry

Bunting provide a total metal separation solution, combining magnetic separators with metal detectors to locate and remove problematic and damaging metal contamination from a diverse range of food products such as chocolate, pet food, grain, orange juice, baked products, meats, and many more.