Glass Industry

Purifying raw materials and removing tramp metal in glass production and recycling

- Rare Earth Roll Separators to remove fine iron and paramagnetic minerals from raw materials such as silica sand;

- Drum Magnets to remove smaller tramp metal from raw materials;

- Metal Detectors to identify any ferrous and non-ferrous tramp metal prior to entering the manufacturing process;

- Eddy Current Separators to separate non-ferrous metals (e.g. ring pulls, bottle tops, etc) from cullet;

- Overband Magnets to remove larger tramp ferrous metal from conveyed cullet

Technical Articles

Glass Industry Products

Overband Magnets

Suspension Magnets

Drum Magnets - Permanent

Pulley Magnets

Glass Industry

Removing Metal Contamination from Glass

- Rare Earth Roll Separators to remove fine iron and paramagnetic minerals from raw materials such as silica sand;

- Drum Magnets to remove smaller tramp metal from raw materials;

- Metal Detectors to identify any ferrous and non-ferrous tramp metal prior to entering the manufacturing process;

- Eddy Current Separators to separate non-ferrous metals (e.g. ring pulls, bottle tops, etc) from cullet;

- Overband Magnets to remove larger tramp ferrous metal from conveyed cullet

Technical Articles

Glass Industry Products

Overband Magnets

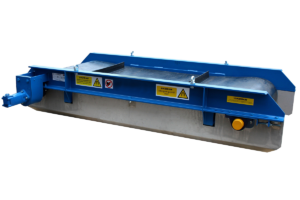

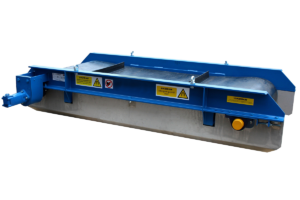

Overband magnets are suspended over conveyors to separate frequently-occurring disruptive tramp ferrous metal and are available as permanent and electromagnetic designs.

Suspension Magnets

Suspension Magnets sit above conveyors to separate occasional tramp ferrous metal and are available in permanent and electromagnetic versions.

Drum Magnets - Permanent

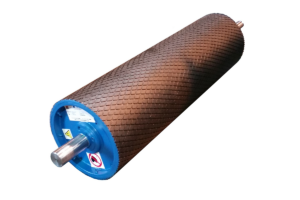

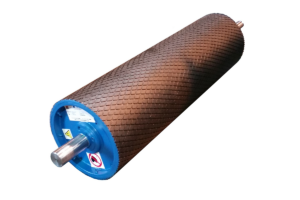

Both low and high-intensity Drum Magnets for continuous removal of free iron and magnetic minerals. Commonly used to purify dry raw materials and cullet when recycling.

Pulley Magnets

Pulley Magnets replace conveyor head pulleys to automatically remove tramp ferrous metal from glass raw materials and cullet in recycling operations.

Rare Earth Roll Separators

High-intensity magnetic separator that removes weakly and paramagnetic minerals from raw materials such as silica sand.

Eddy Current Separators

Separate non-ferrous metals such as aluminium from crushed secondary glass (cullet) to enable the recycling of glass containers.

Stainless Steel Separators

The ultra-high-intensity magnetic separator removes even the weakest magnetic contamination, including small needles, from raw materials and cullet in recycling operations.

Metal Detectors

Industrial and balanced coil metal detectors to locate any metal contamination that may damage crushers, conveyors, and screens.

Overband Magnets

Suspension Magnets

Drum Magnets - Permanent

Pulley Magnets

Overband magnets are suspended over conveyors to separate frequently-occurring disruptive tramp ferrous metal and are available as permanent and electromagnetic designs.

Suspension Magnets sit above conveyors to separate occasional tramp ferrous metal and are available in permanent and electromagnetic versions.

Both low and high-intensity Drum Magnets for continuous removal of free iron and magnetic minerals. Commonly used to purify dry raw materials and cullet when recycling.

Pulley Magnets replace conveyor head pulleys to automatically remove tramp ferrous metal from glass raw materials and cullet in recycling operations.

Rare Earth Roll Separators

Eddy Current Separators

Stainless Steel Separators

Metal Detectors

Magnetic Separators for Glass

The production of glass products, such as bottles, uses raw materials such as silica sand, often mixed with a proportion of recycled glass. Magnetic and metal contamination is found in both the raw material and the recycled glass, and when not removed causes visual and structural defects.

In glass raw materials (including silica sand, soda ash and limestone), the contamination is often in mineral form or as small tramp metal. Magnetic mineral removal requires high-intensity magnetic separation, using strong magnetic forces to attract and remove strong and weakly magnetic minerals. More standard magnetic separators and metal detectors enable the removal of tramp metal (e.g. nuts, bolts, broken process plant).

Magnetic Separators for Cullet in Recycling Operations

Recycled glass contains a wide range of contaminants including metal bottle tops, aluminium foil, and needles. Optimum removal allows the recycled material to become a key material source, highlighting the recyclability of glass, reduction in energy usage, and meeting key global recycling targets.