Metal Detector Solutions at Indian Fabric Exhibitions

By Paul Fears | 04 September 2023

In September 2023, Bunting’s newly appointed Indian representative NPK India is exhibiting at two international textile shows, techtextil India (12-14 September, Mumbai) and Nonwoven Tech Asia (26-28 September, Delhi). The shows provide the ideal platform for Bunting to promote their range of metal detectors for the textile sector.

Metal contamination, commonly in the form of needles and pins, causes costly and time-consuming damage to textile machinery such as rollers. Rollers used in the textile industry create a specific thickness of material. Metal entering the rollers causes damage that leaves an imperfection on the roll surface. Subsequently, the garment has a permanent indent in the material.

To prevent metal contamination damaging the rollers, textile producers install metal detectors prior just prior to the material pressing stage. Vast rolls of material flow across the surface of a metal detector, where any metal contamination is identified and removed, preventing any roller damage.

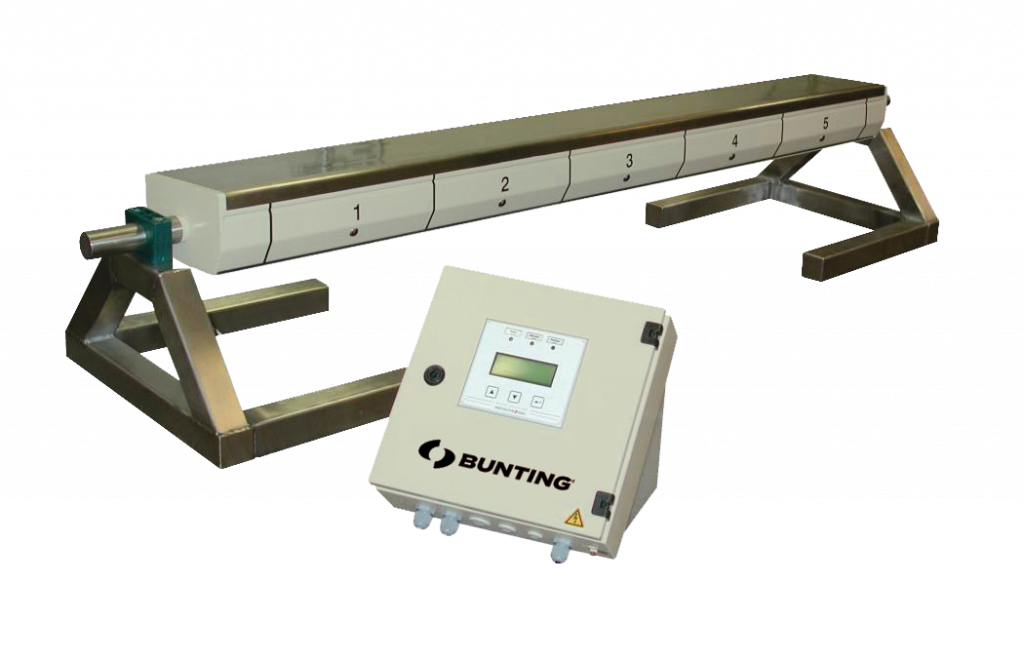

Bunting’s flat-faced Metal Detectors sit under the moving fabric just prior to the rollers. The metal detectors require a minimal metal-free-zone and include an anti-static sensor surface. The highly sensitive and precise metal detector finds all metals, including ferrous, non-ferrous (copper, aluminium and brass), and stainless steel, whether encapsulated or loose. Installation is straight forward, with the metal detector secured in only two-points. Metal detector lengths are variable to suit an application and are stepped in either 150 or 300mm sections.

The Metal Detectors also check for metal contamination in waste fabrics prior to shredding.

In addition to the range of metal detectors, Bunting supplies X-Ray inspection systems. This technology provides a final check of packaged goods and checks for any contamination in the finished product, such as broken needles from the button sewing machines.

“The Indian textile sector is world-leading and these exhibitions provide the perfect platform to show how we can assist in improving their manufacturing process,” explained Bradley Greenwood, Bunting’s European Sales Manager. “Our new local representative, NPK, has a wealth of experience in the industry and we are looking forward to developing new sales opportunities in the region.”

For further information on Metal Detectors for textile applications please contact our technical sales team on:

Email: Michael Allen (mallen@buntingmagnetics.com)

Telephone: +44 (0) 1527 65858

Follow us on social media