Three ElectroStatic Separators for Universities

By Paul Fears | 03 June 2025

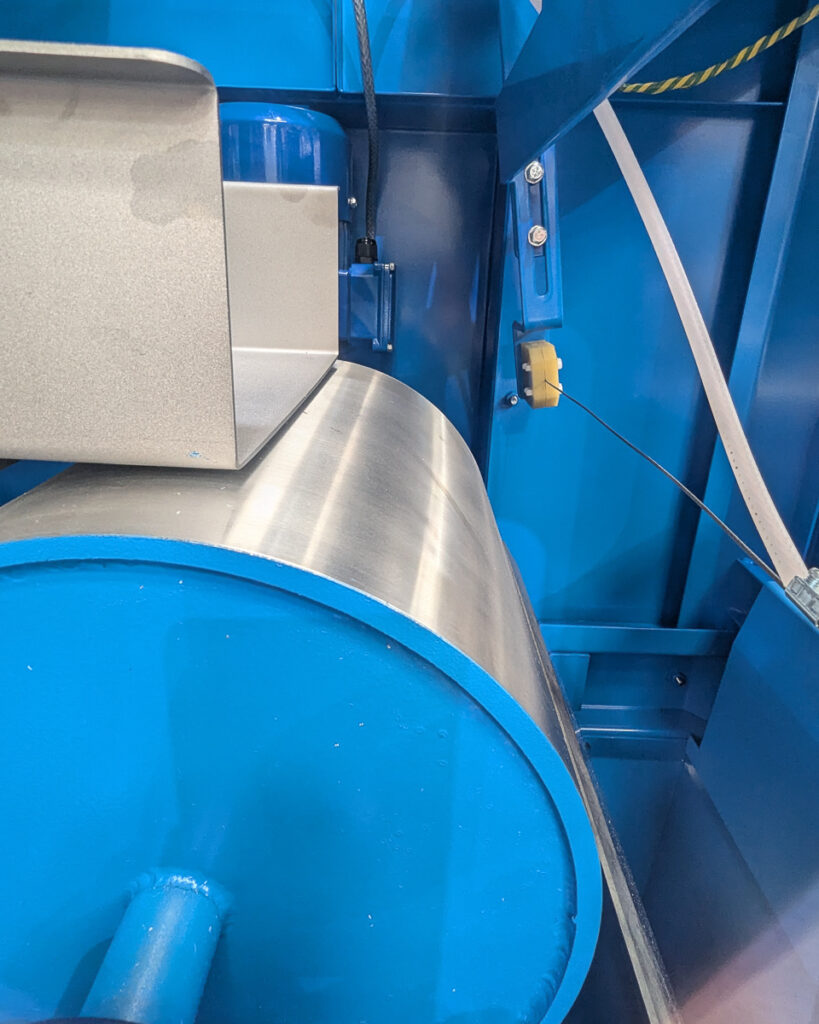

Research into the separation and recovery of fine metals from waste materials, such as batteries and electronics, is driving a growth in orders for Bunting’s laboratory-scale ElectroStatic Separators. In May 2025, Bunting Magnetics completed the manufacture of three laboratory-scale ElectroStatic Separators destined for research bodies in the UK, Finland and Morocco.

An ElectroStatic Separator exploits the difference in electrical conductivity between various materials in a feed material to produce a separation. The ability to produce a separation depends on a number of key material characteristics including a material’s conductivity, moisture content and particle size range.

Conductivity Differences Drive Separation

In operation, the ElectroStatic technology use conductivity differences between insulators (e.g. plastics) and conductors (e.g. copper and aluminium) to obtain a separation on an earthed roll. A controlled mono-layer flow of material is fed via a vibratory feeder onto the earthed roll. Whilst the insulators are pinned to the earthed roll via an image force, the conductors lose their charge and are thrown from the roll by the centrifugal force generated by the rotating roll. Certain degrees of separations is also possible between particles of different conductivity.

ElectroStatic Separators commonly feature in the later stages of a recycling plant after the removal of magnetic metals using magnetic separators and coarser non-ferrous metals with Eddy Current Separators. The fine material fed to an ElectroStatic Separator has a tight particle size distribution with good particle liberation.

Recycling Research at Universities

Universities use the ElectroStatic as one stage of separation in a recycling process. Presently, many research projects focus on the recovery and recycling of metals and materials present in lithium and other batteries as used in electric cars and a wide range of other technologies. The recovery of precious metals from electric waste (e-waste) is also an important area of research.

Even though Bunting Magnetics work with many research organisations, providing testing on a wide range of separation equipment including ElectroStatic Separators, Universities specialising in recycling research acquire the technology as part of a process. This expands the testing possibilities at their research centre. Bunting Magnetics provides training for laboratory technicians to ensure the ElectroStatic Separator potential is optimised.

“We are witnessing a growth in the range of applications for the ElectroStatic Separator,” explained Professor Neil Rowson, Bunting Magnetics’ Laboratory Manager. “Often the ElectroStatic Separator is only considered when all other separation avenues have been exhausted. We are working closely with many Universities, research institutes and companies, assessing and further developing this technology to successfully solve exceptionally difficult separation problems.”