UK Metal Contaminated Food Recalls

By Paul Fears | 30 April 2024

In the first four months of 2024, the UK Food Standards Agency issued four (4) alerts regarding metal contamination in food products that had reached the public, just one less than the five reported in the whole of 2023.

The metal contaminated food products were supplied by leading UK supermarkets including Lidl and Asda, as well as major food manufacturing companies including Unilever. The alerts warned consumers to not consume the contaminated food products and return them.

Metal Contamination Food Alerts in 2024 (January to April)

The specific food alerts were:

Lidl – Tower Gate Cookies (January 2024)

Lidl recalled Tower Gate Cookies including Soft Baked Cookies – Triple Chocolate, Lemon, and Chocolate Chip Cookies due to concerns about metal contamination.

- UK Food Standards Agency: Lidl recalls various Tower Gate cookies because of the possible presence of metal

Taj Foods – Taj Chopped Spinach (March 2024)

Taj Foods recalled Taj Chopped Spinach because of metal contamination concerns. The 450g pack was only sold in Asda and Eden Farms.

- UK Food Standards Agency: Taj Foods recalls Taj Chopped Spinach because it may contain pieces of metal

Signature Flatbreads UK – Village Bakery 8 Tortilla Wraps White

Signature Flatbreads UK took the precautionary step of recalling Village Bakery 8 Tortilla Wraps White because of a possible presence of metal following possible tampering.

- UK Food Standards Agency: Signature Flatbreads UK recalls Village Bakery 8 Tortilla Wraps White because of possible presence of metal

Unilever – Magnum Classic Ice Cream

Unilever recalled Magnum Classic Ice Cream Sticks (3x100ml) because of concerns about metal contamination.

- UK Food Standards Agency: Unilever recalls Magnum Classic Ice Cream Sticks 3 pack because they may contain pieces of metal

How Does Metal Contamination Occur?

Food is commonly contaminated with metal during the manufacturing process. Wear and failure of processing equipment can introduce rogue items of metal into the process and unless there is sufficient metal removal and detection equipment in place, the contaminated product will reach the consumer. The consumption of metal contaminated food can cause mouth and throat lacerations, and damage teeth.

Metal Contaminated Products

The metal contaminated products included ice cream, baked products, and bagged leafy greens. The exact nature and origin of the metal contamination is unknown. However, in all cases, the cost in terms of reputation and product recall is substantial.

Removing and Detecting Metal Contamination

Most food processing plants feature systems to remove and identify metal contamination prior to the product leaving the premises. During the manufacturing process, magnetic separators attract and securely hold any ferrous metal or magnetically susceptible plastic contamination. To maximise metal capture, most of the magnetic separators use ultra-strong rare earth magnets (neodymium or samarium cobalt).

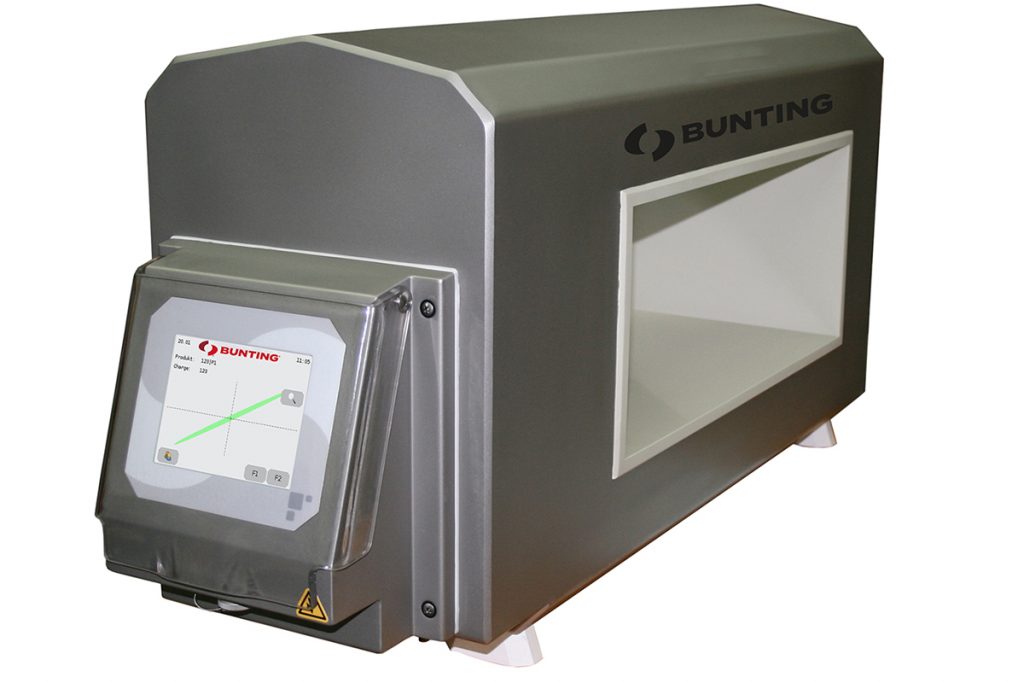

Although metal detectors feature in the food manufacturing process, they are commonly located prior to and after packing. The high-sensitivity free-fall and tunnel-type metal detectors locate even the smallest ferrous or non-ferrous metal shard hidden in a food product.

Regular Auditing

Both the magnetic separators and metal detectors require regular auditing to confirm the performance meets the production requirements. Changes in the process, suppliers, and ingredients can all affect the performance and allow metal to pass through into the final product.

Bunting engineers regularly conduct in-depth audits, physically checking the magnetic integrity of the magnetic separators and sensitivity of the metal detectors. Following the onsite audit a report is produced and forms part of any company’s ongoing process quality improvement plan.