Description

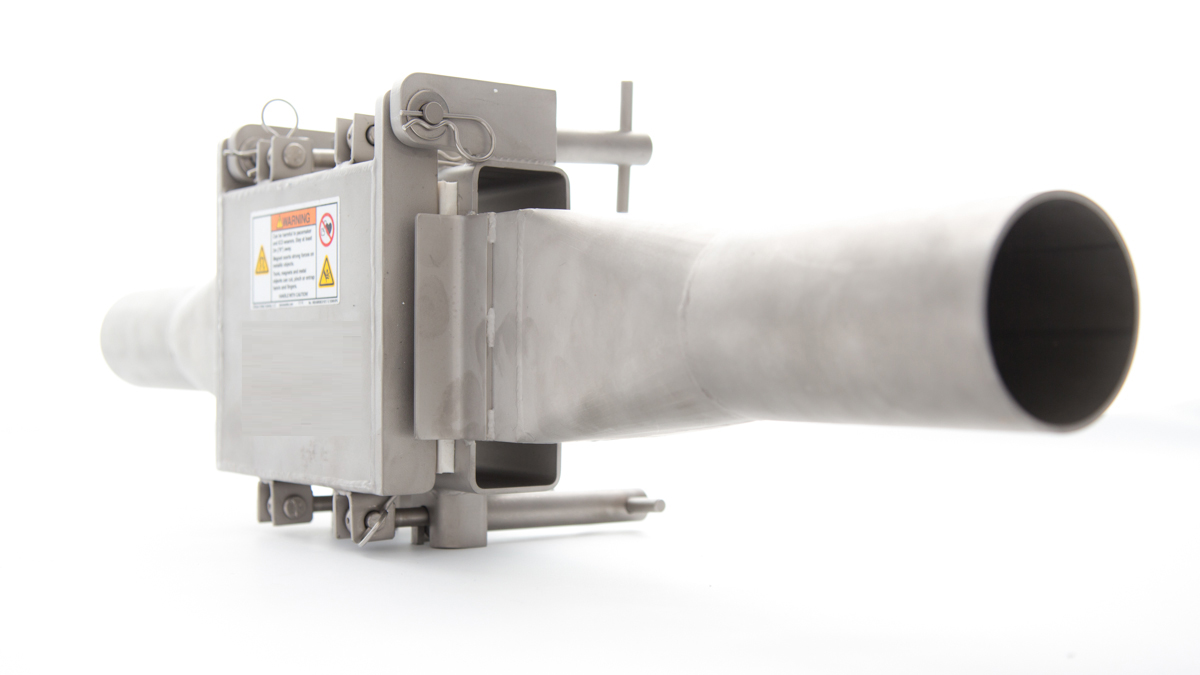

Inline Magnets are popular with companies transporting materials through pipes due to the ease of installation and effective separation of tramp ferrous metal. The non-obstructive design suits applications in many different applications including food processing and plastics. The body design and finish are either standard or food sanitary.

The Inline Magnet is designed to easily connect into pipelines with diameters between 50 and 250mm. A Plate Magnet, mounted on one side of a tube, attracts and holds ferrous metal contamination. During scheduled maintenance, the hinged Plate Magnet is unfastened, swung out of the product stream and cleaned.

The Inline Magnet features a Plate Magnet which projects a strong magnetic field across the width of the pipe. Depending on the nature and size of the tramp ferrous metal, the Plate Magnet is either constructed from Ceramic Ferrite or Neodymium Rare Earth. Ceramic Ferrite Magnets produce a deep magnetic field in contrast to the exceptionally strong but shallower field generated by Neodymium Rare Earth. The nature of the ferrous metal contamination determines the type of magnet.

The Plate Magnet is commonly fitted with a magnetic-field enhancing tapered step, which traps captured ferrous material behind a lip and out of the product flow.

Operation

In operation, material is fed into the body of the Inline Magnet either by gravity or pneumatically. As the material flows through the body, the strong magnetic field of the Plate Magnet attracts and securely holds any tramp ferrous metal. This is a continuous process, with the captured ferrous metal being removed during scheduled maintenance on a frequency in accordance with the level of ferrous metal contamination.

Models

Inline Magnets are available with both standard-strength Ceramic Ferrite and high-strength Neodymium Magnet in two models:

- Gravity Inline Magnets (GIMs) – Suited for pipelines when material is falling under gravity.;

- Pneumatic Inline Magnets (PIMs) – Designed for installation in pneumatic conveying systems with a top pressure rating of 15psi. Ideal for horizontal installation.;

Applications

Inline Magnets are extremely versatile and are used in a wide range of applications including:

- Food processing plants;

- Plastic manufacturing operations;

- Ceramics;

- Powder and bulk handling;