Metal Contaminated Food Alerts 2020

By Paul Fears | 01 September 2020

In 2020, the UK’s Food Standards Agency reported seven (7) cases of metal contaminated foods (in 2019, there were eight (8)). Each case was very different and ranged from chocolates to sandwiches. The associated cost, in terms of lost revenue due to recalled products and company reputation, is considerable.

In this article, we review each Food Safety Alert in 2020, considering the source of such metal contamination and methods to ensure that such metal is found and removed prior to the product leaving the plant.

Cakes Containing Metal

Seery’s Heatherfield Ltd recalled Bridge Bakery Carrot, Lemon, and Triple Chocolate Cakes due to concerns about the presence of small pieces of metal. The cakes were sold in Lidl stores in Northern Ireland.

With multiple ingredients used in bakery products, metal contamination often enters the food process with the raw material (e.g. flour, chocolate, etc).

Metal Contaminated Bread Sticks

In June, Savour Bakes Bread Sticks recalled due to the possible presence of metal. The product is manufactured by the Athenian Family Bakery and sold in Aldi stores. The family bakery, with a 100 plus year history of baking, is based in Holargos in Greece.

Although the source of the metal has not been confirmed, metal contamination commonly enters the process with the raw material (i.e. flour, seeds, etc).

Ice Lolly Contamination

Wall’s Mini Calippo (orange and lemon-lime) recalled by multi-national Unilever as the potential presence of metal makes the product unsafe to eat. This highlights the challenge of maintaining metal-free food and that such problems do not only affect smaller food producers.

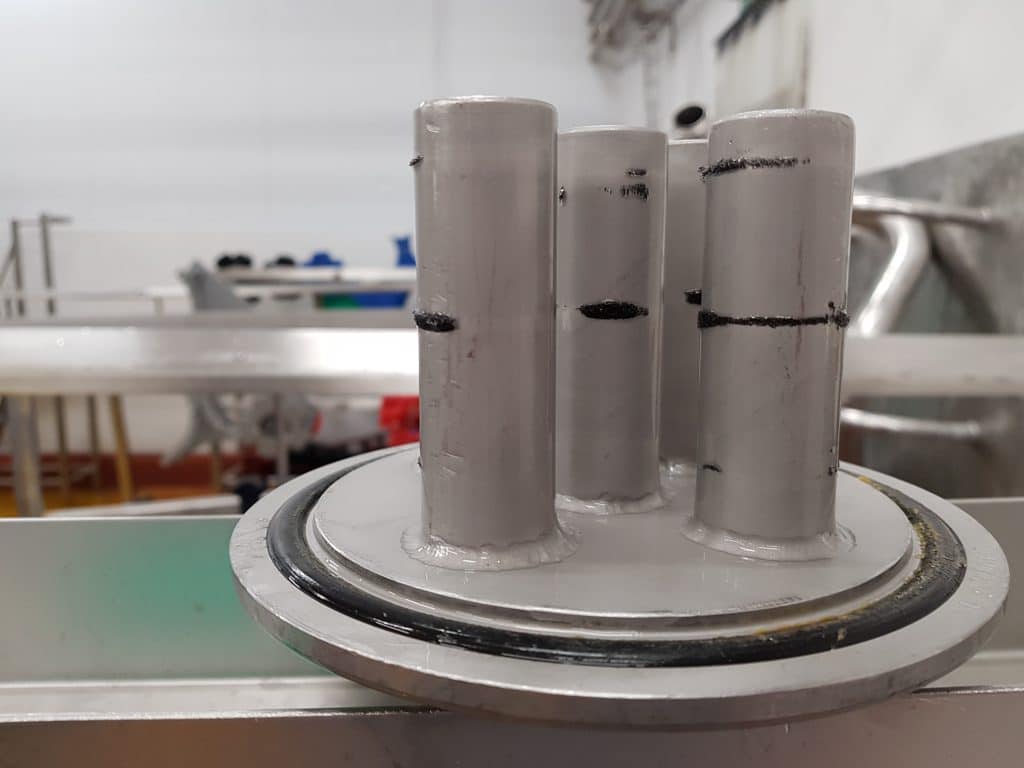

Magnetic Liquid Traps are commonly used in pipelines to capture fine ferrous metal occurring in fruit juices, although the exact source of the metal in this case is unconfirmed.

- Technical product information: Magnetic Liquid Traps

Metal Contaminates Lasagne and Sandwiches

There were two metal contaminated food alerts in March.

The vegetable lasagne may be gluten-free, but it was not metal-free and the product was recalled by Amy’s Kitchen. The contamination was reported as being in the form of metal-shavings and may have been the result of process equipment failure or contamination during plant maintenance.

Amy’s Kitchen is a family-run business established in 1987. This metal-contamination problem is damaging both in terms of public relations and cost.

The second alert in March was for Chicken & Stuffing Sandwiches sold by the Co-op. The report does not specify whether the metal occurred in the chicken, stuffing or bread or whether the sandwiches were manufactured by a supplier.

In similar plants, finished and packed products such as sandwiches are passed through a Metal Detector prior to shipment. This identifies any packages contaminated with metal and prevents this type of negative publicity.

- Technical product information: Metal Detectors

Metal Present in Chocolate

Two food alerts due to the presence of metal were reported in February.

Multinational confectionery manufacturer Mars Wrigley announced the recall of chocolate Revels pouches in the UK. The small pieces of metal were the result of mechanical breakdown.

- Related blog: Getting Metal Out of Chocolate

Another multinational food producer, Müller, recalled 14 different products due to concerns regarding metal contamination. The metal was caused due to a production fault, which could have been from wear or failure.

Processing machinery both wears and occasionally fails, both of which can contaminate the process with metal. Installing a series of magnetic separators and metal detectors both removes and finds any metal prior to the finished product leaving the manufacturing plant.

- Related blogs: 8 Metal-in-Food Alerts in 2019

Free Onsite Survey

Food manufacturing processes often evolve over time, with changes made to improve the quality of the products and efficiency of the plant. Commonly, these changes result the incumbent Magnetic Separators and Metal Detectors being in the wrong location or no longer working at optimal efficiency.

Bunting provide a third party onsite audit of installed metal separators. This involves reviewing and checking the performance and integrity of the installed equipment. Magnetic Separators are tested for strength and positioning within a process. Metal Detectors have their metal detection sensitivities reviewed to ensure that these still meets the quality standards of the producer.

Once completed, Bunting submit a report which can be used as part of the quality management system. Such audits are conducted on an agreed frequency, either once per annual or biennial.

Food Related Technical Articles

For further information on removing and detecting metal contamination in the food manufacturing process, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Follow us on social media