Rising UK Metal Packaging Recycling Tonnage

By Paul Fears | 22 July 2020

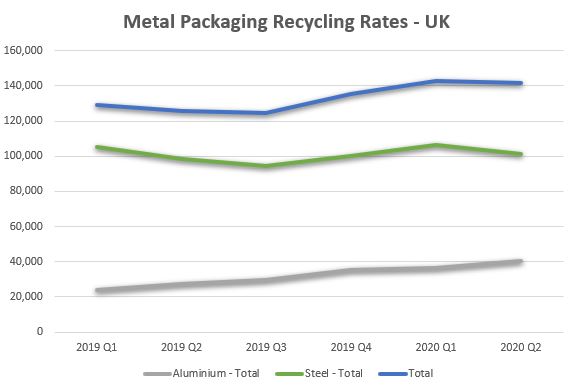

The latest data from the UK Environment Agency’s National Packaging Waste Database for quarter 2 2020 shows a 9.7% rise on quarter 1 2019 in the tonnage of recycled and recovered Used Beverage Cans (UBCs) and metal packaging. However, whereas the recycled tonnage of aluminium packaging has steadily increased over the period, there has been a 5% fall in the amount of steel in quarter 2 on quarter 1 2020.

Recycled Packaging Processing

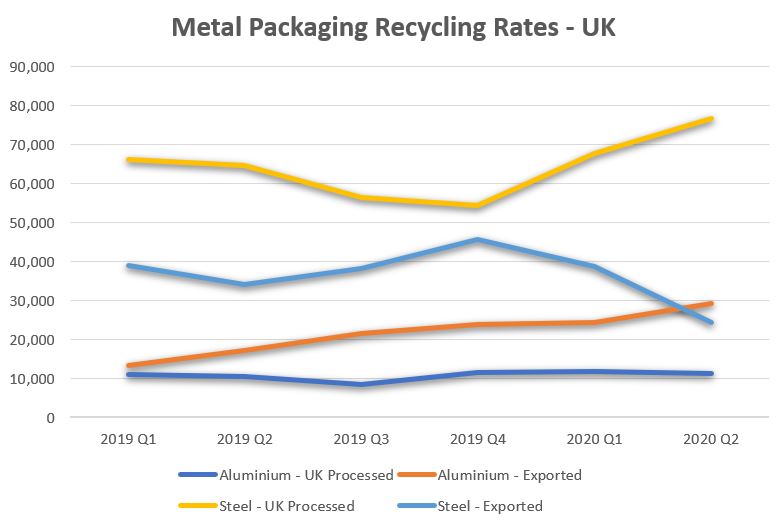

The reclaimed metal packaging is both processed in the UK and exported overseas. Between quarter 1 2019 and quarter 2 2020, the amount of aluminium processed in the UK increased by 9%, with a growth of 121% in exports. In quarter 1 2019, the split between UK processing and exports was 45/55%, whereas in quarter 2 2020 this had changed to 28/72%.

In contrast, the percentage of steel packaging processed in the UK rose to 76% (Q2 2020) from 63% (Q1 2019). In tonnage terms, the actual tonnage of steel packaging exported for processing fell 37% from 38,915 (Q1 2019) to 24,445 tonnes (Q2 2020).

The recovery and subsequent sale of metal packaging is a vital source of income for many waste processors. Further rises in recovery are anticipated during 2020.

Technological Advances in Separation Equipment

As highlighted in Resource Recycling (July 21 2020), the upgrading of separation equipment is driving the increased recovery of UBCs.

Steel packaging is recovered using magnetic separators. Magnetic forces are used to attract and separate the steel from non-metallic waste. Typical magnetic separators used in steel packaging recovery include:

- Overband Magnets (Electro and Permanent) – suspended over a conveyor to lift and separate steel from conveyed pre-sorted waste;

- Electro Drum Magnets – ideal for recovering steel from mixed refuse streams and incineration ash;

Aluminium packaging is recovered using Eddy Current Separators. In a dynamic separation, a high-speed rotating magnetic rotor forcibly ejects aluminium from non-magnetic waste materials.

Presently, Bunting engineers are working with many UK waste processors and assessing ways to improve the recovery of the valuable metal packaging. This often involves adjusting the magnetic separation or eddy current separation equipment already installed or the process.

For additional information on Magnetic Separators or Eddy Current Separation or to request a free onsite review, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Follow us on social media