Separating Ferrous Metals When Recycling Printer Cartridges

By Paul Fears | 19 October 2020

A high-strength Rare Earth Drum Magnet separates the ferrous metal constituent of shredded secondary laser and toner cartridges at BCMY’s UK cartridge recycling operation. The efficient removal of ferrous metal protects downstream shredders, whilst also maximising the purity of the end recycled product.

- Technical product information: Drum Magnet

BCMY Ltd, based in Lancing in West Sussex, is one of the UK’s premier processors of used printer cartridges and receives materials from across the UK and Europe.

Recycling Printer Cartridges

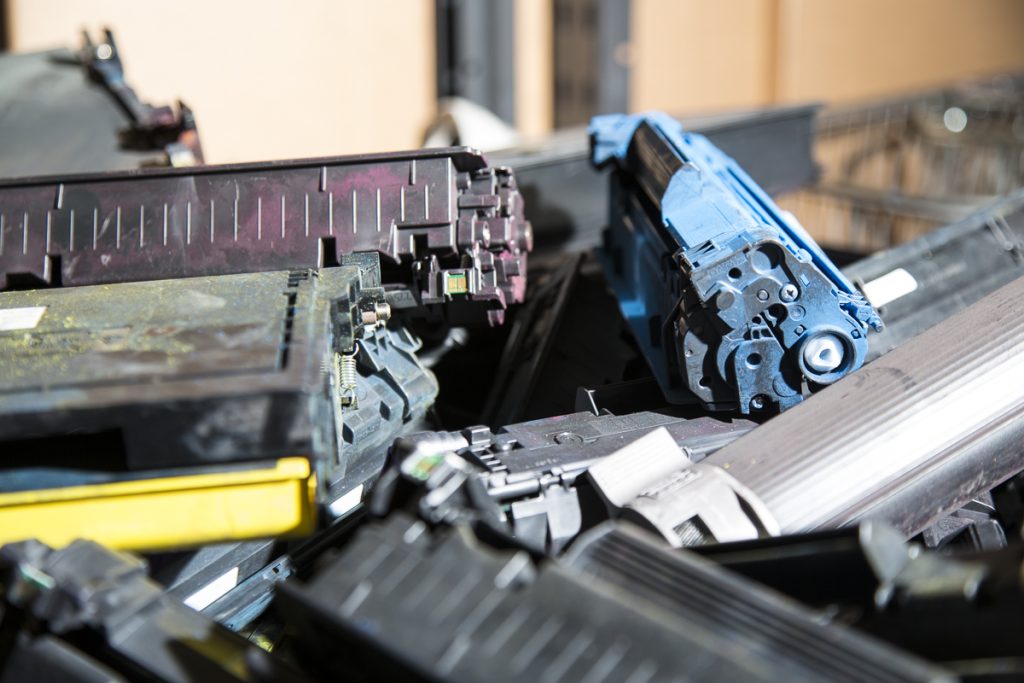

At present, only approximately 15% of the 250 million ink and 25% of the 40 million toner cartridges used in Western Europe are recycled. The majority end up in landfill, where it can take more than 1,000 years to decompose whilst also posing a threat to ground water pollution.

Post-consumer processing requires specialist knowledge as toner and printer cartridges are classed as a hazardous material. This is due to the explosion risk arising from the small particle size of the toner dust.

The Cartridge Recycling Process

On receipt of the used laser & toner cartridges, BCMY decides whether the item is reusable or need recycling. Approximately 62% of all cartridges received are reused, although the growing number of poorer quality replicas and compatibles (approx. 15%) originating from the Far East and a growth in remanufactured cartridges (approx. 20%) means that an ever-increasing number follow a path for internal recycling.

There is a high global demand for specific virgin empty cartridges despite increased competition from the Far East. However, the overall percentage of collected reusable cartridges is falling. There are limited disposal options for high volume cartridges producers with the introduction of tighter waste legislation and a reduction in industry capacity to deal with the non-reusable cartridges. With landfill no longer being a legal option for high volume producers, waste to energy plants is a favoured option due to the cartridges’ high calorific value. However, this option also has environmental implications.

At the UK plant, BCMY specialise in the physical recycling of the non-reusable cartridges. Hazardous toner dust is removed, leaving co-mingled rigid plastic and metal. The empty cartridge shells are fed into a slow-speed shredder for size reduction and liberation, before travelling up an incline conveyor and onto a strong Bunting Drum Magnet. The Drum Magnet separates all magnetic materials such as steel components, springs and other small ferrous metals as well as ceramic magnets. The cleansed plastic fraction is further shredded for additional liberation before being passed over an Eddy Current Separator to separate non-ferrous metals such as aluminum.

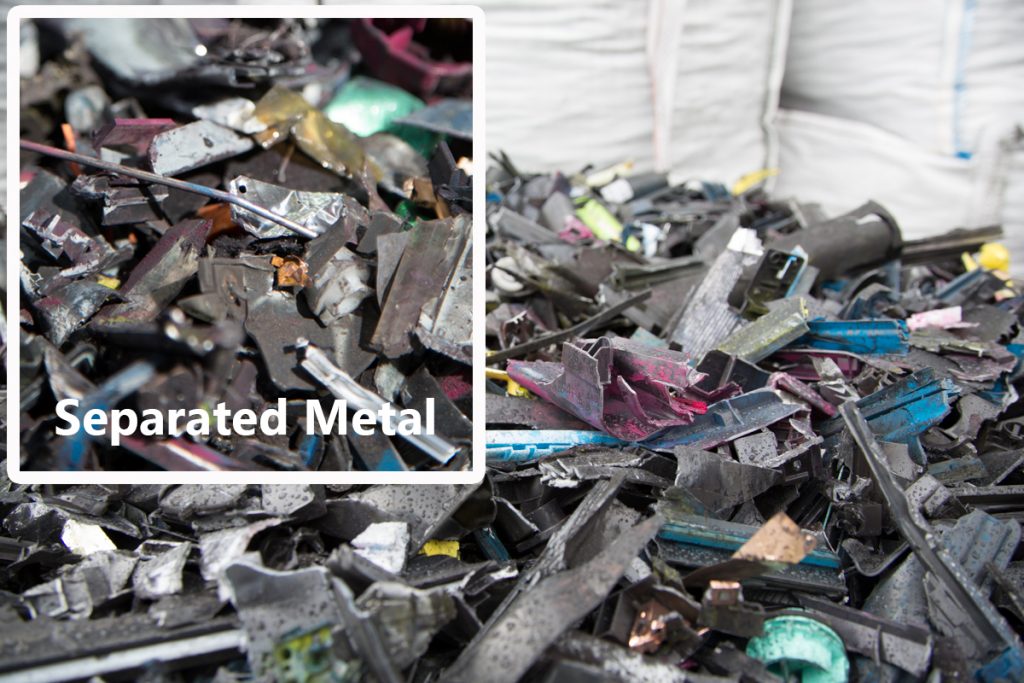

Drum Magnet Separates Metal

The Drum Magnet features a stationary magnetic element positioned inside a rotating stainless-steel shell. The magnetic element is constructed using high-strength, permanent, neodymium rare-earth magnets. The Drum Magnet (300mm – 12” diameter by 300mm – 12” wide) is mounted inside a dust-enclosed housing and driven by a direct shaft-mounted electric motor.

Material is conveyed on an inclined conveyor up to the Drum Magnet’s feed hopper and then cascades down onto the rotating shell. The strong magnetic field attracts and holds magnetic materials, carrying them underneath and out of the field so that they drop into a separate container. The plastic non-magnetic material is unaffected by the magnetic field and follows a normal trajectory into a separate collection bin.

There is approximately a 42% metal content in each cartridge, which is then sold as an end product. The recovered plastic, which is made up of (PS,ABS,PET,PP,POM, and HDPE), is also resold for a wide variety of applications including the production of plastic wood. The hazardous toner powder is used as a colorant in the manufacture of plastic, as well as a filler in tarmac and marine paint for boats.

Related Recycling Case Histories

For additional information on magnetic separators, eddy current separators, metal detectors, and electrostatic separators used to separate and recover metals, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

All photographs taken by Paul Fears Photography

Follow us on social media