What is an Axial and Radial Magnetic Field?

By Paul Fears | 17 August 2020

Rotary Magnetic Separators, such as the Drum Magnet and Pulley Magnet, are designed with a specific type of magnetic field. The type of magnetic field is considered when looking at any application and when deciding which design will achieve a customer’s separation objective.

For these rotary designs of magnetic separator, there are two types of magnetic field:

- Axial

- Radial

So what is an Axial or Radial Magnetic Field and why is it so important?

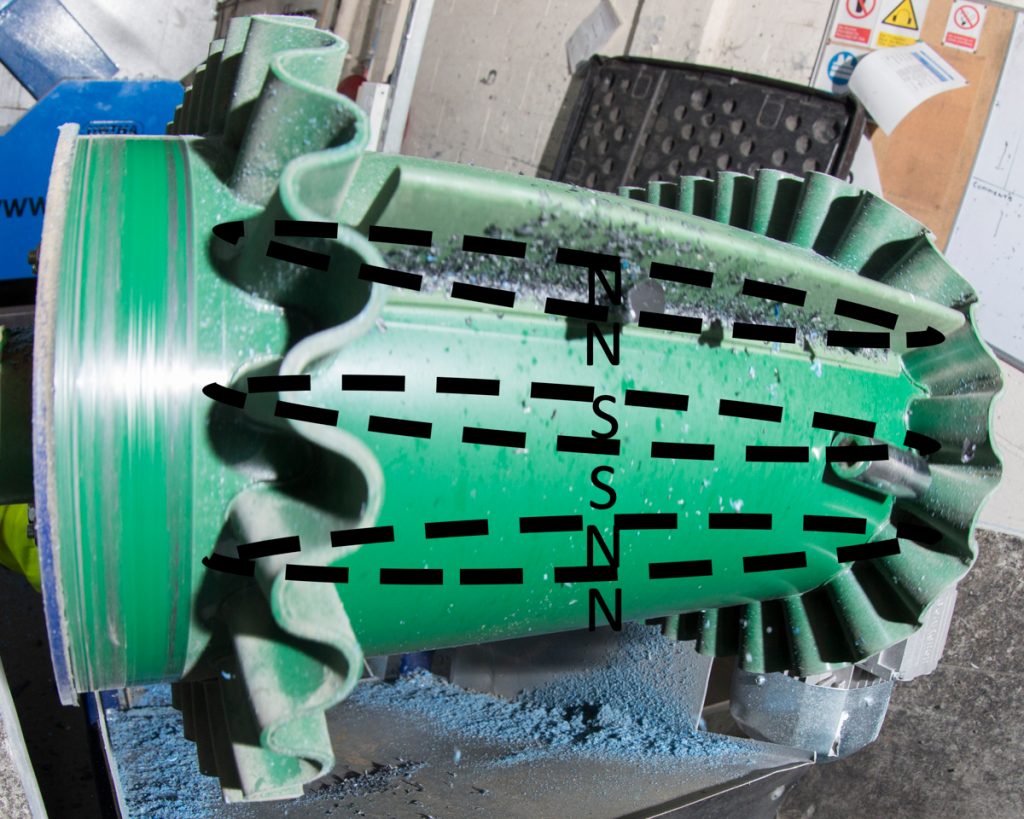

Axial Magnetic Field

An Axial magnetic field stretches across the width of the rotary Magnetic Separator. Magnetically susceptible material entering into the field is attracted to the point of highest magnetic intensity (the pole) but is then dragged through an area of weaker field (between the poles) and onto another pole by the motion of the conveyor or drum.

This type of magnetic field is ideal when there could be a high level of entrapped non-magnetic material captured by the Magnetic Separator. The motion of moving between the poles results in non-magnetic material being released as the magnetic item ‘tumbles’ in the field. However, with this type of magnetic field there can be a reduced separation performance.

The Axial magnetic field is ideal when the separation objective is to maximise the purity of the recovered ferrous metal. The ‘tumbling’ effect releases entrapped non-magnetic material. Recovery rates of ferrous metals may be slightly lower.

Magnetic separators with an axial field are commonly used when recovering ferrous metal in recycling operations (e.g. incineration ash, general shredded household refuse, car frag). They include Drum Magnets (both permanent and electro) and Pulley Magnets

Technical product information:

Radial Magnetic Field

The Radial Magnetic Field has poles running in the same direction as the rotation of the conveyor or drum and with the flow of the material. Magnetically susceptible material is attracted to the points of highest magnetic intensity (the poles) and held until it is dragged out of the magnetic field underneath the conveyor or Drum.

This type of magnetic field is ideal when maximising the separation of magnetic metal. However, entrapment of non-magnetics can occur, reducing the purity level of the separated metal.

Typical applications suited to radial designs of magnetic separator include the recovery of magnetic minerals in mineral processing and the removal of ferrous metal in recycling operations (e.g. glass cullet, plastic, WEEE, car frag, feldspar or silica sand purification, etc).

The radial shaped magnetic field features on Drum Magnets, Pulley Magnets, Rare Earth Roll Separators and Induced Magnetic Roll Separators.

Technical product information:

Selection Criteria

Deciding on the type of magnetic field for any specific application is dependent on a number of key factors including:

- Separation objective (recovery or removal);

- If recovery, purity target for the recovered metal;

- If removal, separation target of the ferrous component;

- Capacities that commonly determine burden depths;

- The particle size of the ferrous metal and the non-metallic material;

For additional information on Magnetic Separators with an axial and radial magnetic field, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Follow us on social media