Iron Separation Technology at Ceramics UK Show

By Paul Fears | 10 June 2019

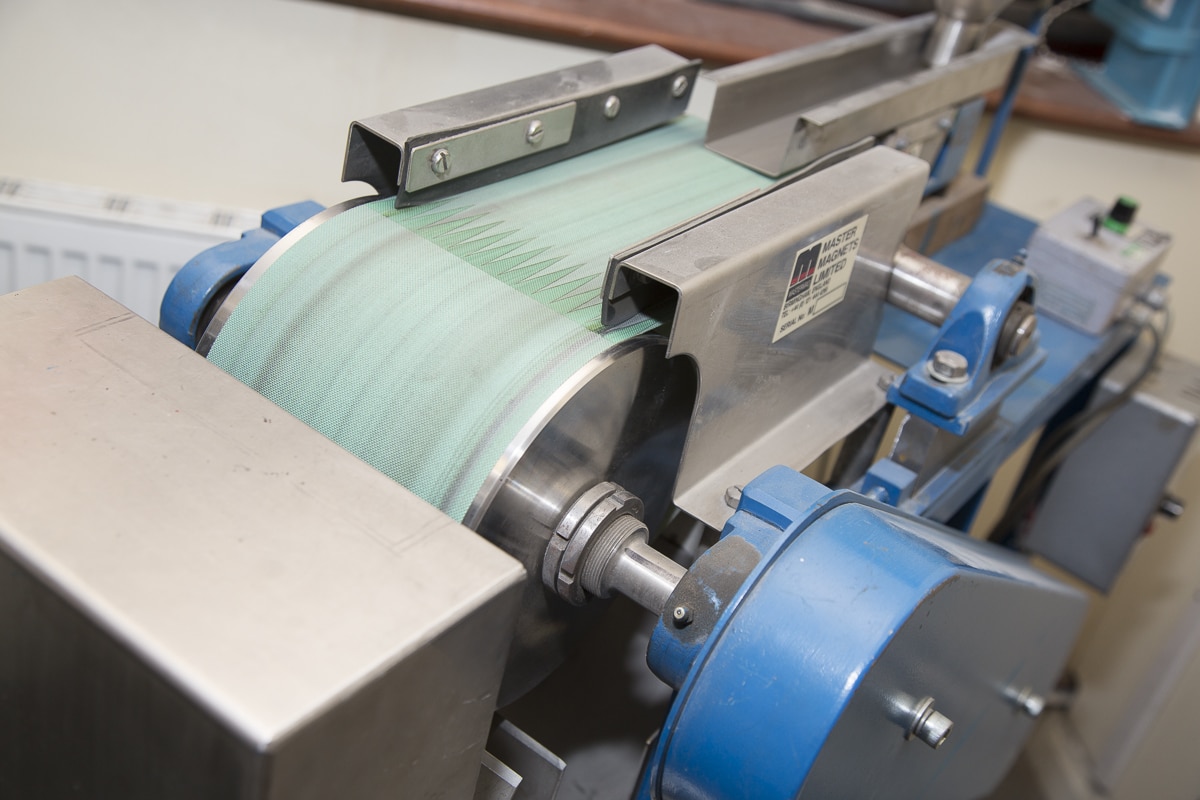

Successfully removing fine iron from ceramic slips and glazes is vitally important in any ceramics plant. Such iron contamination is removed using high intensity magnetic separators like those on display on the Bunting and Master Magnets stand 1517 at the Ceramics UK show (10-11 July 2019, Telford, United Kingdom).

Electro Magnetic Filter on display at Ceramics UK

Iron contamination causes surface defects (black spots or holes), weakens the ceramic structure to crack, and reduces the whiteness of glaze. Most of the raw materials used to manufacture ceramics contain iron bearing minerals that then enter the ceramics manufacturing process.

Bunting has a wide range of high intensity magnetic separators to remove the iron contamination or iron bearing minerals are various stages within the ceramics plant.

Raw materials, such as feldspar, zircon and silica sand, are commonly purified at source. Most non-metallic mineral processing plants include dry magnetic separators such as the Rare Earth Roll Separator and Induced Roll Magnetic Separator.

Rare Earth Roll Separator

Once entering the plant manufacturing ceramic tiles, tableware, sanitaryware or figurine, magnetic separators remove iron from both the slip, glaze and spray dry powder. The designs include simple Permanent Rare Earth Tube Magnets, commonly configured in a trap or as a grid, and Electro Magnetic Filters. Ultra-strong Tube Magnets attract and hold fine iron, which is then periodically manually removed. High intensity Electro Magnetic Filters attract and hold magnetic to a centrally located matrix, before initiating a self-cleaning sequence to remove all captured contamination. At the Ceramitec show in 2018, Master Magnets secured an order for two large Electro Magnetic Filters from a Turkish ceramic producer on the stand.

An Electro Magnetic Filter, Grate Magnets and Neodymium Rare Earth Tube Magnets will be on show on stand 1517.

“The UK has such a rich history of producing high quality ceramics,” said Dave Hills, Bunting Group’s Head of Sales, “and it is a great to see a UK-based ceramics focused show. Our relationship with the ceramics and non-metallic minerals industry stretches back to the first days of Master Magnets. We evolved with the industry helping reduce product loss due to iron-related defects. We are looking forward to speaking with UK-based and international ceramics producers at the show.”

For further information on testing at the Master Magnets laboratory, on the range of Laboratory Magnetic Separators supplied by Master Magnets, or to discuss a specific project, please contact us via:

Email (to Paul) at press@buntingeurope.com

Via the website

Telephone: +44 (0) 1527 65858

Photographs by Paul Fears Photography

Follow us on social media

For further information or to discuss a specific project, please complete the following form