Ceramics

Nine High-Intensity Electromagnetic Filters for European Ceramics Producer

A major European producer of luxury ceramic sanitaryware has ordered nine (9) high-intensity Electromagnetic Wet Filters from Bunting Magnetics. The Electromagnetic Wet Filters are destined for plants across Europe including Poland, Portugal, and the Ukraine. Electromagnetic Wet Filters have ultra-high-intensity, background magnetic fields (from 3,500 up to 10,000 Gauss) to separate fine iron and paramagnetic…

Read MoreBunting Develops High-Intensity Electromagnetic Dry Filter

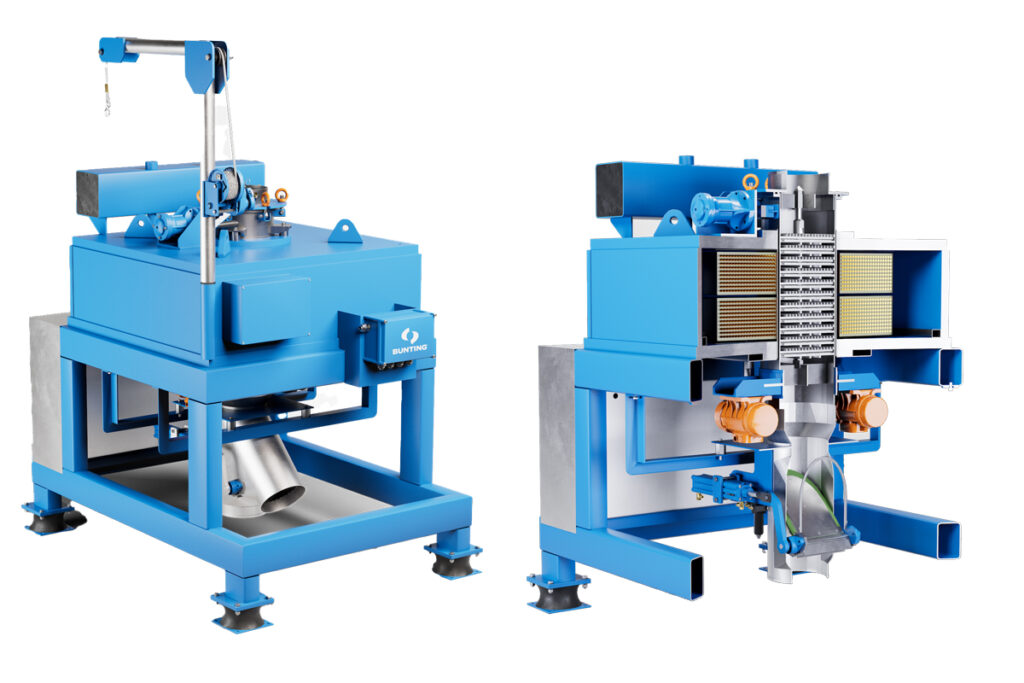

Bunting has developed a new Electromagnetic Dry Filter to remove free fine iron from powders. The high-intensity magnetic separator generates ultra-strong magnetic fields to capture ferrous particles present in difficult-to-process fine materials. The new technology enhances magnetic separation in a diverse range of applications found in mineral processing, chemical and pharmaceutical production, ceramics, and recycling.…

Read MoreBunting Develops High-Intensity Electromagnetic Wet Filter

Bunting has developed a new Electromagnetic Wet Filter with an ultra-high-intensity, background magnetic field (from 3,500 up to 10,000 Gauss). The magnetic separation technology separates fine iron and paramagnetic minerals from liquids and slurries and is used in the ceramics, mineral processing, and recycling industries, as well as cleaning wastewater in steel production and power…

Read MoreNecessity of Cleaning Magnetic Separators

When on site, our Technical Sales Engineers often take opportunity to check the installed magnetic separators. At many sites, this results in a conversation about the required cleaning frequency for a permanent magnetic separator such as a Drawer Filter Magnet, Plate Magnet, or Liquid Magnetic Separator. This is when captured ferrous metal is manually removed…

Read MoreHigh-Intensity Magnetic Separation at Ceramitec 2024

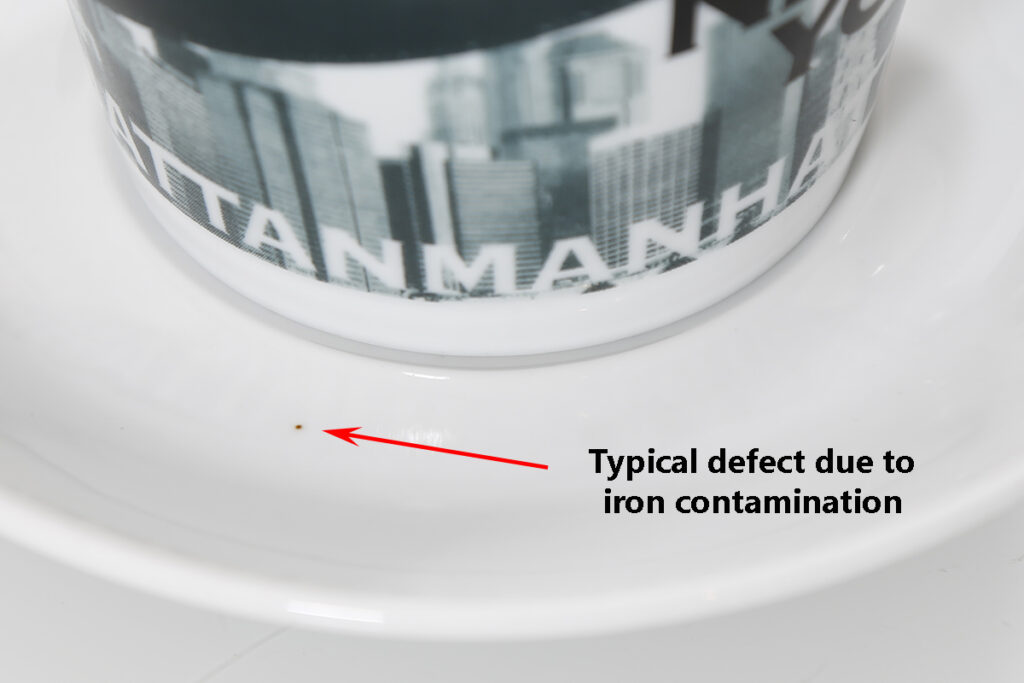

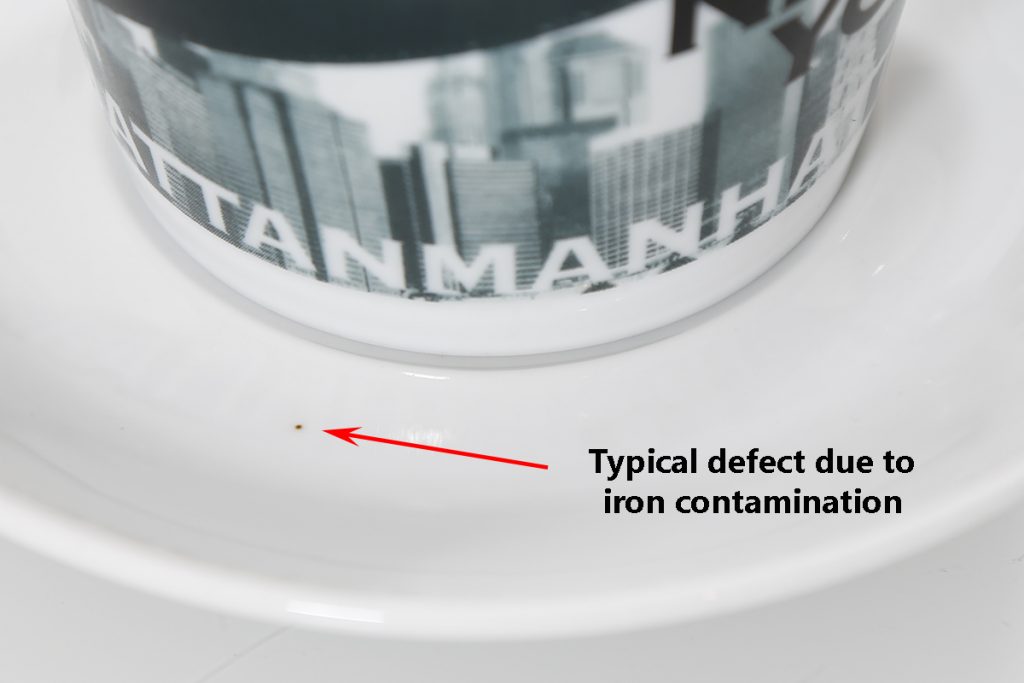

High-intensity magnetic separators reduce rejects, rework, and increase ceramic whiteness. On Bunting’s stand A6 323D at Ceramitec 2024 (9-12 April, Munich, Germany), ceramic engineers and ceramic mineral processors can find out about the latest high-intensity magnetic separation technology for both wet and dry processes. Keeping Ceramic Glazes, Slips and Bodies Free of Magnetics Fine iron…

Read MoreHigh Intensity Magnetic Separation at XVIII ECerS

The XVIIIth Conference of the European Ceramic Society takes place in Lyon, on 2-6 July 2023. On stand 19, Bunting is highlighting the necessity of using high-intensity magnetic separators to remove iron, iron-bearing and paramagnetic minerals to reduce defect rates and improve surface brightness. Paramagnetic Minerals and Fine Iron Contamination Materials used in the manufacture…

Read MoreElectro Magnetic Filter for European Ceramics Producer

A leading German ceramic manufacturer is cleaning ceramic glaze with a high-intensity Electro Magnetic Filter designed and manufactured by Bunting. The successful removal of fine magnetics reduces finished product rejects and increases surface brightness. High-Intensity Electro Magnetic Filters The Electro Magnetic Filter provides one of the most effective methods of removing problematic fine iron and…

Read MoreSeparating Problematic Metal at POWTECH 2022

At POWTECH 2022 (27-29 September, Nuremberg, Germany), Bunting’s focus is on the separation of problematic metal from dry materials. On stand 3A-613, visitors will see the latest magnetic separators and metal detectors that effectively remove tramp metal and very fine iron from a wide range of granules and powders. POWTECH is the leading European trade…

Read MoreHigh-Intensity Magnetic Separators at Ceramitec

High-intensity magnetic separators play a key role in the manufacture of ceramics and the processing of ceramic raw materials, as highlighted at Ceramitec 2022 on Bunting’s stand (on stand C1:511). Keeping Ceramics Iron-Free Fine iron and magnetic minerals cause defects in any ceramic product, whether that is tableware, sanitaryware, tiles or technical ceramics. The iron…

Read More30 Year Magnetic Separator Market Evolution

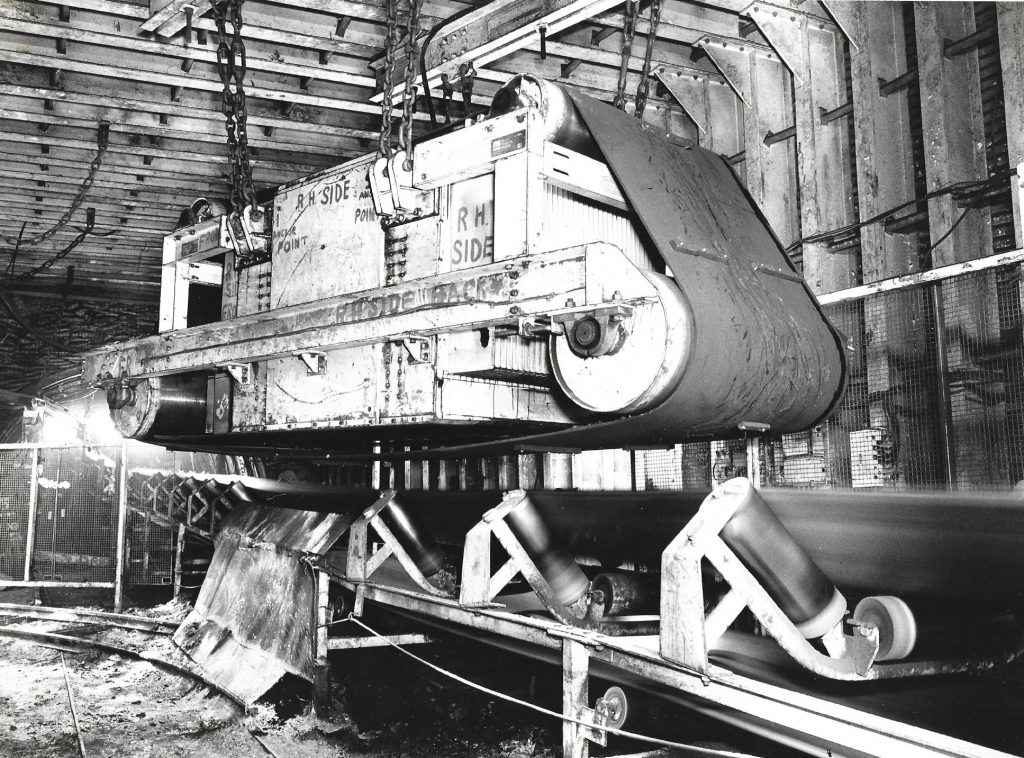

Our Press Officer, Paul Fears, first became involved in marketing magnetic separators in 1989. In this blog, Paul looks back at the evolution of the magnetic separator market. When I started my career in 1989, I had no comprehension of the importance of magnetic separators. I quickly discovered that the technology was used in every…

Read More