Recycling Growth Dependent on Technology

By Paul Fears | 16 March 2021

Annual events such as the UK’s Recycling Week, the Global Recycling Day and Earth Day provide the perfect platform for reflection and planning. Successful and extensive recycling reduces the pressure on the planet’s finite resources, whilst also providing desperately needed environmental protection. Many experts predict that the failure to radically change the way waste is produced and managed will result in irreversible damage. The future of the planet and humanity is at risk.

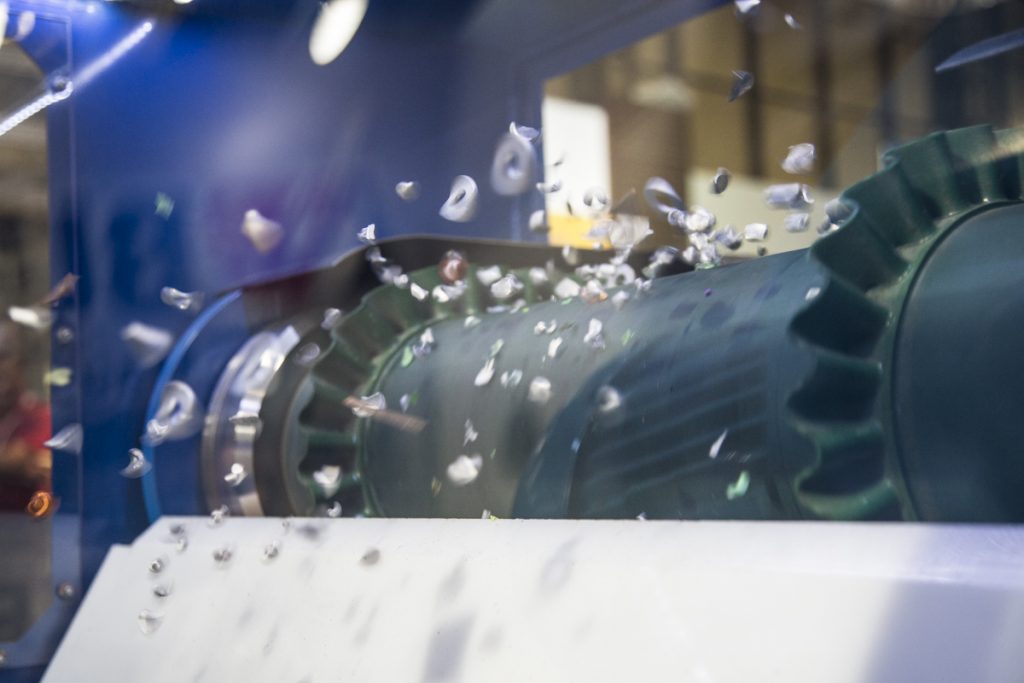

Technology plays a vital role, enabling the recovery of materials such as metals (e.g. steel and aluminium) and the cleansing of waste for reuse such as plastic.

Metal Recovery for Recycling

Many historians trace the first evidence of metal recycling back to Roman times and the recycling of old bronze coins. Metal is one of the most recyclable materials on Earth. In the report World Steel Recycling in Figures 2015-2019 the Bureau of International Recycling (BIR) states that in 2019 630 million tonnes of steel scrap is recycled every year.

In 2020, the International Aluminium Institute (IAI) reported (International Aluminium Institute publishes global recycling data) that not only is 75% of the 1.5 billion tonnes of aluminium ever produced still in productive use, but 30 million tonnes of aluminium scrap is recycling annually. Indeed, Marlen Bertram, IAI’s Director – Product Stewardship states ‘Rapid population and economic growth over the coming decade mean that global demand for aluminium will double through to 2050, and this will be met by 50% to 60% recycled metal.’

Although there are many successful manual metal recycling initiatives, technology provides the best method of recovery.

Ferrous Metal Recovery

Magnetic Separators recover ferrous metals, with Overband Magnets lifting steel beverage cans out of household waste and large Electro Drum Magnets separating steel from shredded automobiles and white goods. Higher strength Drum Magnets even recover small ferrous metals from shredded electronic waste (WEEE).

- Technical Product Information: Magnetic Separators

In recent years, new technology enables the recovery of fragmented stainless-steel. When passed through a shredder, the edges of the cut metal become very weakly magnetic. Separators with exceptionally strong magnetic fields, such as the patented SSSC Magnetic Separator, attract and change the trajectory of the stainless-steel enough to enable separation from non-magnetic materials.

Non-Ferrous Metal Recovery

Even though non-ferrous metals are non-magnetic, metals such as aluminium and zinc are recovered using a magnetic Eddy Current Separator. The reaction of a conductive metal in a rotating magnetic field enables the separation from non-conductive materials. This allows the recovery of aluminium cans from household refuse, and non-ferrous metals from shredded end-of-life vehicles.

- Technical Product Information: Non-Ferrous Metal Separation

More recently, advances in ElectroStatic Separation have increased the capability of recovering smaller metals such as fine copper wire and precious metals from electronic waste (WEEE).

Removing Metal Contamination from Waste

Despite being a ‘recycling hero’, metal can also be a villain. Waste materials such as plastic are commonly contaminated with both ferrous and non-ferrous metal, preventing the material’s recycling. Successful reuse and/or recycling is not possible without the removal of the metal.

Ferrous metal is the most common contaminant and also the easiest to remove. When the metal is large, such as spanners and iron bars found in plastic waste bales, Overband Magnets, Plate Magnets and Magnetic Head Pulleys provide effective separation.

As the ferrous metal reduces in size, the separation difficulty increases. Shredded or granulated plastic waste is often passed through a Drawer Filter Magnet, which features a series of high-strength neodymium Tube Magnets to capture the ferrous metal.

The separation of non-ferrous metal is often more difficult, especially when smaller in particle size. When the concentration of non-ferrous metal contamination is high, an Eddy Current Separator provides effective separation. For waste materials with low levels of metal contamination, recyclers use Metal Detectors, with the material being passed through on a conveyor or by gravity feed. The electronic coil within the Metal Detector head identifies any metal (ferrous or non-ferrous) and either stops the conveyor or automatically rejects a batch of material.

- Technical Product Information: Metal Detectors

When the non-ferrous metal particles are very small with a low mass, such as in the form of foil, the ElectroStatic Separator is adopted. This uses the conductivity of the non-ferrous metal to remove and separate such contamination.

Future Developments

Technological advances already enable the recycling and reuse of an increasing amount of waste materials. Indeed, simply broadening the use of existing technology will significantly increase the proportion of recycled waste.

At our Bunting-Redditch Customer Experience Centre, companies conduct controlled tests on waste materials from across the world. These tests prove the separation capabilities of a wide range of metal separators, and enable companies to design plants to maximise recovery and purity.

The combined efforts of companies designing and manufacturing separation technology and those recycling waste materials solve recovery or separation problems. Working together will the single aim of recycling more waste materials.

Despite the rightful concerns, there are also many reasons to be positive.

Related Recycling Articles

For further information on Magnetic Separators, Eddy Current Separators, and ElectroStatic Separators for metal recovery in recycling applications or to discuss a specific project including undertaking tests in our Customer Experience Centre, please contact our technical sales team on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Photography: Paul Fears Photography

Follow us on social media