6-Year-Old Electro Overband Magnet Refurbishment

By Paul Fears | 08 February 2021

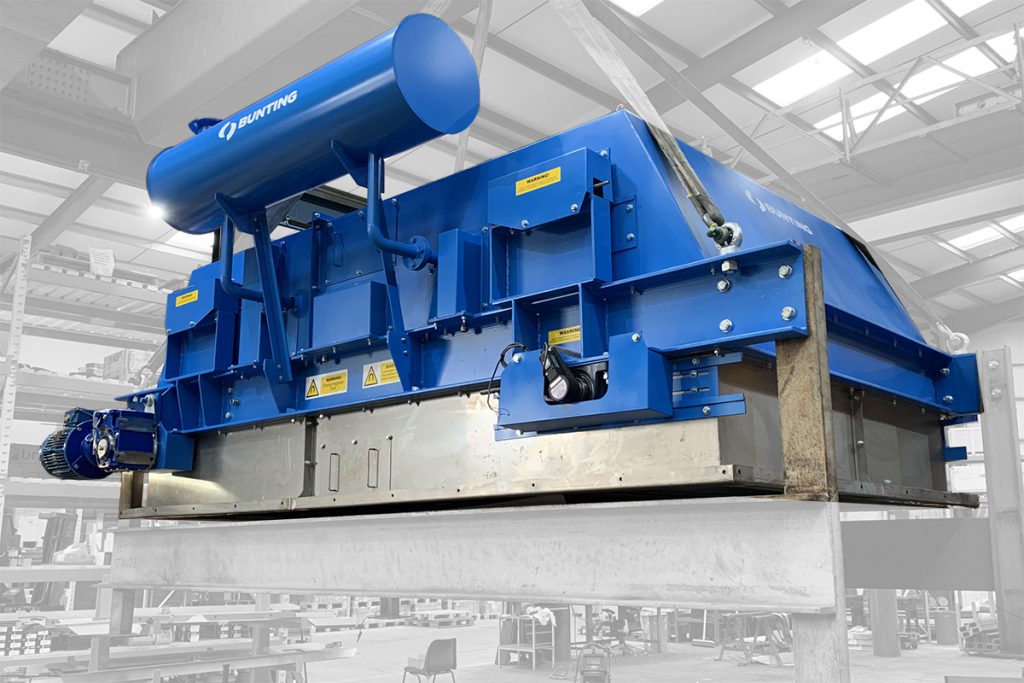

Repair and refurbishment convert a well-used, functional magnetic separator into almost new, further extending the life of the equipment. One of Bunting’s latest repair and refurbishment projects involved a 6-year-old Electro Overband Magnet.

The oil-cooled Electro Overband Magnet model 155 OCW 45 CB separates tramp ferrous metal from biomass pellets in a bulk handling terminal at a UK port. The large Overband Magnet weighs 9.5 tonnes and is 4m long, 1.285m high and 2.18m wide.

The Electro Overband Magnet had operated for 24 hours a day for 6 years in challenging conditions. The separation performance had not changed during that time, but regular inspections identified mechanical wear and tear. Rather than replace the still-operational Electro Overband Magnet with a brand new model, Bunting recommended a complete refurbishment.

- Technical Product Information: Overband Magnets

Electro Overband Magnet Refurbishment

On arrival at the Redditch plant, Bunting’s engineers undertook a complete review, identifying the scope of the work and the parts needing replacement. The team referenced the original drawings and work instructions for specification of components and design. The parts needing replacement included:

- The cooling oil inside electro magnet, which was drained, safety disposed of, and replaced;

- A new conservator tank, which was manufactured and fitted;

- The idler bearing sealing bar, which was re-made;

- Bearing guards, which were fabricated on site along with a stainless-steel lower guard;

- Key components including a temperature probe, eyebolts, fasteners, bearings, seals and a breather;

- A new endless discharge belt;

Once in possession of all the new parts, the refurbishment team disassembled the Electro Overband Magnet. In broken down parts, the unit was shot blast and totally repainted. Once re-assembled, the Electro Magnet then underwent extensive operational tests, ensuring the electromagnetic coil functioned efficiently and in accordance with the original specification. Once complete, the refurbished Overband Magnet was undistinguishable from a brand-new unit.

Even though the refurbishment was extensive, the total cost was significantly lower than purchasing a brand-new Electro Overband Magnet.

Magnetic Separator Refurbishment and Repair

Many magnetic separators operate in difficult and arduous environments causing significant wear and tear. The high-quality original design and build of Bunting’s magnetic separators means that such equipment can be repaired and refurbished, extending life and saving on capital investment costs. Typical equipment repaired and refurbished by Bunting includes:

- Electro and Permanent Overband Magnets;

- Electro Drum Magnets;

- Eddy Current Separators;

“Repairing and refurbishing magnetic separators and eddy current separators injects new life into well-used equipment,” explained Adrian Coleman, the General Manager of Bunting-Redditch. “Our equipment often operates in extremely difficult conditions for prolonged periods of time and will be subject to extensive wear and tear. Offering a repair and refurbishment service provides a lower and non-capital cost solution.”

Related Articles

For further information on Bunting’s repair and refurbishment service or to discuss a specific project, please contact our technical sales team on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Follow us on social media

For further information or to discuss a specific project, please complete the following form