Coal

Magnetic Separation in Mining and Mineral Processing

Magnetic separators are commonplace in most mining and mineral processing operations. However, the term ‘magnetic separator’ encompasses a diverse range of specialist separation equipment with the ability to separate widely different materials such as large tramp metal and paramagnetic minerals. Magnetic separators for the mining and mineral processing sectors are broadly differentiated into two ranges. …

Read MoreSolving Quarrying and Mining Tramp Metal Problems

Tramp metal exists in all mining and quarrying operations. The problematic contamination is difficult to avoid. The nature of mining and quarrying – extracting ore and aggregate using large heavy equipment – results in a wide variety of tramp metal contaminating the mined material. Such metal needs identifying and removing before potentially causing costly damage…

Read MoreModified ToughFlex® Belt for Overband Magnets

Bunting has joined forces with Smiley Monroe to modify a ToughFlex® belt for Overband Magnets. The new belt is more resistant to excessive wear in arduous working conditions. Overband Magnets have a permanent or electromagnetic block mounted between two pulleys over which continuously runs a cleaning belt. In operation, the Overband Magnet is suspended over…

Read MoreSingle, Twin and Tri Pole Overband Magnet Development

Bunting has developed three designs of Permanent Crossbelt Overband Magnet (PCB), with different magnetic polarity, to suit an ever-expanding range of applications. Overband Magnets are mounted over conveyors to separate ferrous metal from non-magnetic material and are commonly used in industries including mining, quarrying, recycling, and wood. The magnetic field of a Permanent Crossbelt Overband…

Read MoreMagnetic Metal Free Areas under Overband Magnets

A common question asked when a client is installing an Overband Magnet or Suspension Magnet is whether the conveyor idlers, frame and housing could become magnetically induced. When installed suspended above a conveyor, the Overband Magnet and Suspension Magnet work by projecting a magnetic field down and through material transported on a conveyor. This magnetic…

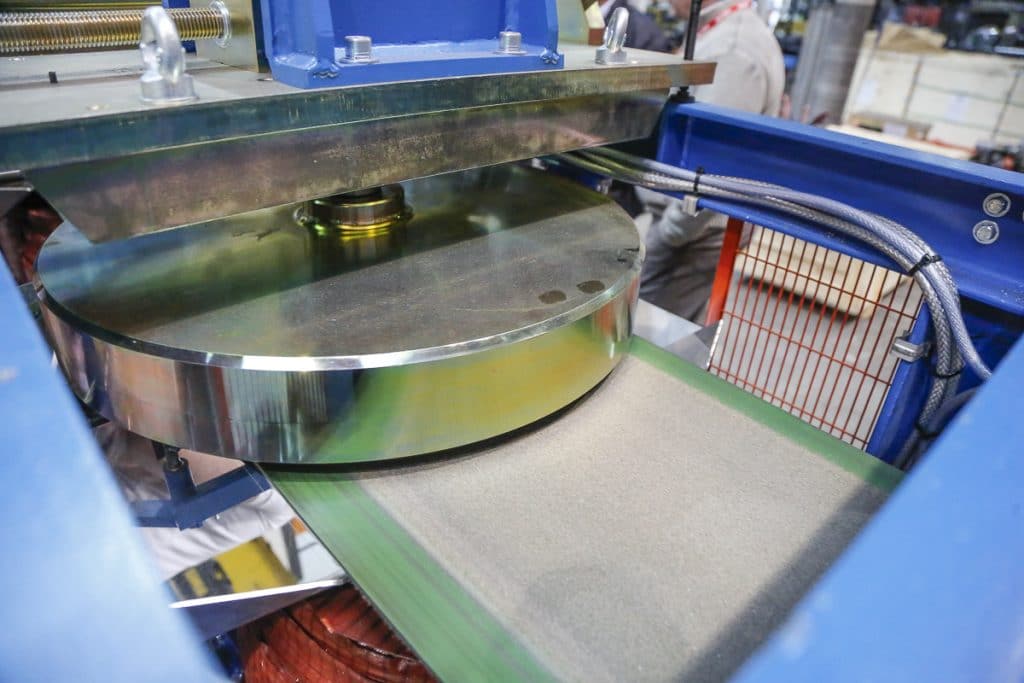

Read MoreBenefits of the Overband Magnet Armoured Belt

The highest wear part on an Overband Magnet is the belt that transfers the separated metal away from the conveyor and into a collection area. In order to reduce such wear, Bunting developed a special lightweight armouring for the rubber belt. The Overband Magnet Armoured Belt is in operation in recycling, mining, quarrying and bulk…

Read MorePermanent Overband Magnet Selection Criteria

Permanent Overband Magnets are commonplace in most mines and quarries, removing tramp ferrous metal and protecting crushers, screens and conveyors against damage. Overband Magnets are also widely used in recycling, recovering ferrous metals and protecting shredders against metal damage. However, there are many different designs of Permanent Overband Magnet, developed to suit specific applications. Understanding…

Read MoreEddy Current Separator and ElectroMax Sales Growth in 2021

The demand for metal separators increased in 2021 on 2020, with exceptional growth in sales of both Eddy Current Separators and ElectroMax Overband and Suspension Magnets. Sales growth followed an expansion in representation in overseas markets and increasing manufacturing capacity at Bunting’s Redditch facility in the UK. At the Redditch manufacturing plant, Bunting specialise in…

Read MoreThe Crusher’s Arch Enemy – Tramp Metal

Crushing quarried aggregate is a key process stage of most quarries and when recycling demolition waste. Effectively protecting the crusher from rogue tramp metal damage prevents production losses and repair costs. The wide range of available crushing technology enables the production of optimally sized aggregate. Whereas Jaw and Gyratory designs commonly feature as primary crushers,…

Read More6-Year-Old Electro Overband Magnet Refurbishment

Repair and refurbishment convert a well-used, functional magnetic separator into almost new, further extending the life of the equipment. One of Bunting’s latest repair and refurbishment projects involved a 6-year-old Electro Overband Magnet. The oil-cooled Electro Overband Magnet model 155 OCW 45 CB separates tramp ferrous metal from biomass pellets in a bulk handling terminal…

Read More