Quarrying

Magnetic Separation in Mining and Mineral Processing

Magnetic separators are commonplace in most mining and mineral processing operations. However, the term ‘magnetic separator’ encompasses a diverse range of specialist separation equipment with the ability to separate widely different materials such as large tramp metal and paramagnetic minerals. Magnetic separators for the mining and mineral processing sectors are broadly differentiated into two ranges. …

Read MoreSolving Quarrying and Mining Tramp Metal Problems

Tramp metal exists in all mining and quarrying operations. The problematic contamination is difficult to avoid. The nature of mining and quarrying – extracting ore and aggregate using large heavy equipment – results in a wide variety of tramp metal contaminating the mined material. Such metal needs identifying and removing before potentially causing costly damage…

Read MoreModified ToughFlex® Belt for Overband Magnets

Bunting has joined forces with Smiley Monroe to modify a ToughFlex® belt for Overband Magnets. The new belt is more resistant to excessive wear in arduous working conditions. Overband Magnets have a permanent or electromagnetic block mounted between two pulleys over which continuously runs a cleaning belt. In operation, the Overband Magnet is suspended over…

Read MoreAtherton Material Handling Installs Bunting Suspension Electro Magnet

Atherton Material Handling has installed a Bunting Suspension Electro Magnet at a calcium carbonate quarry in Melton, UK. The Suspension Electro Magnet removes tramp ferrous metal prior to a metal detector, reducing the number of metal detection trips and increasing productivity. Atherton Material Handling originally contacted Bunting to find a solution to the problem of…

Read MoreMetal Detectors Prevent Plant Damage at Plasmor

Plasmor has installed three Bunting metal detectors to locate tramp metal and prevent damage to processing plant at their building block manufacturing site in Heck, East Yorkshire, UK. Plasmor Limited produce a wide range of innovative and high-quality building blocks for commercial, industrial, residential and prestigious construction projects. Established in 1959, Plasmor Limited remains privately…

Read MoreSingle, Twin and Tri Pole Overband Magnet Development

Bunting has developed three designs of Permanent Crossbelt Overband Magnet (PCB), with different magnetic polarity, to suit an ever-expanding range of applications. Overband Magnets are mounted over conveyors to separate ferrous metal from non-magnetic material and are commonly used in industries including mining, quarrying, recycling, and wood. The magnetic field of a Permanent Crossbelt Overband…

Read MoreMagnetic Metal Free Areas under Overband Magnets

A common question asked when a client is installing an Overband Magnet or Suspension Magnet is whether the conveyor idlers, frame and housing could become magnetically induced. When installed suspended above a conveyor, the Overband Magnet and Suspension Magnet work by projecting a magnetic field down and through material transported on a conveyor. This magnetic…

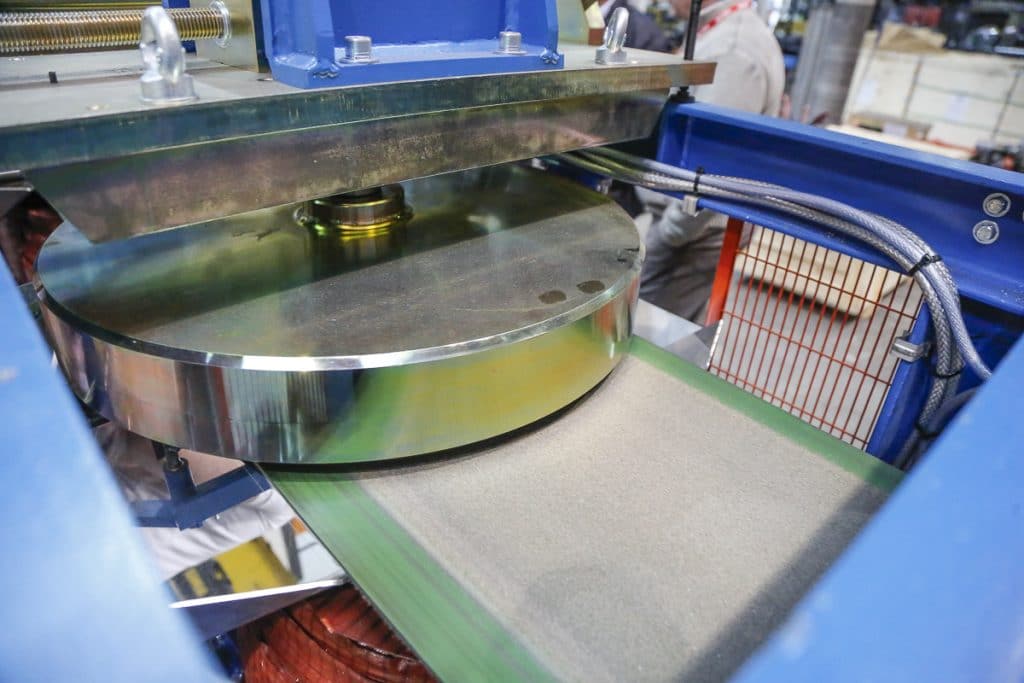

Read MoreBenefits of the Overband Magnet Armoured Belt

The highest wear part on an Overband Magnet is the belt that transfers the separated metal away from the conveyor and into a collection area. In order to reduce such wear, Bunting developed a special lightweight armouring for the rubber belt. The Overband Magnet Armoured Belt is in operation in recycling, mining, quarrying and bulk…

Read MoreHillhead Success for Bunting

The Hillhead quarrying, construction and recycling show (Buxton, UK, 25-27 June, 2024) was blessed with a decent spell of weather for the throngs of international visitors. Bunting’s ideally located stand, on the downslope towards the pavilion, was busy for the whole 3-days. Bunting has exhibited at Hillhead for decades, with metal detectors, magnetic separators and…

Read MoreBunting ElectroMax-Plus Protects Aggregate Crushers

A UK construction materials company installed an ElectroMax-Plus Overband Magnet to remove tramp ferrous metal from quarried material prior to crushing. Bunting specified, designed and built the powerful electromagnetic Overband Magnet at their UK manufacturing facility in Redditch. The ElectroMax-Plus Installation The ElectroMax-Plus Overband Magnet is installed at magnesium limestone quarry in Derbyshire, United Kingdom. …

Read More