Magnetic Disc Separator Processes Beach Sands

By Paul Fears | 23 March 2020

Bunting’s latest Magnetic Disc Separator (MDS) is for processing and separating key minerals from a beach sands deposit. The three-stage Magnetic Disc Separator is destined for a mineral processing operation in Africa.

The Magnetic Disc Separator

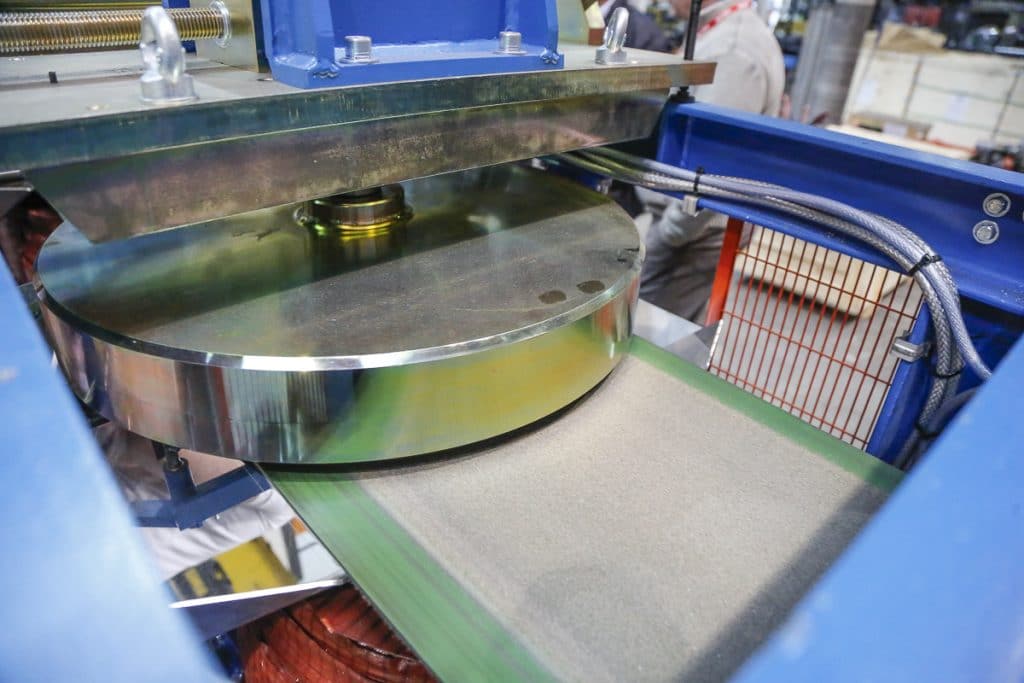

Magnetic Disc Separators (MDS) enable an accurate separation of minerals with varied magnetic susceptibilities. Typically, a Magnetic Disc Separator will feature up to three high-intensity electromagnetic discs, each set at a different height from a feed conveyor. The first disc will be set the furthest from the feed material, in order to extract only the most magnetically susceptible particles. The second and third discs are set at lower gaps, increasing the magnetic force at each disc and therefore separating different grades of magnetic material. Magnetic intensity can also be further adjusted by varying the current of each coil to suit each client’s specific mineral separation requirements.

Unlike other designs, Bunting have a designated coil for each magnetic disc. The coil and magnetic disc relationship enable precise adjustment of the magnetic field at each stage and ensures accurate generation of the optimum magnetic field.

The Beach Sands Project

In this latest project, the beach sands mineral mix includes ilmenite, garnet, monazite, silica sand, rutile, and zircon. Prior to determining the specification of the production-scale Magnetic Disc Separator, Bunting undertook comprehensive material tests in their mineral processing laboratory at Redditch. The controlled tests determined the magnetic power required at each stage to produce a successful separation.

The production-scale Magnetic Disc Separator has six distinct separation stages. In operation, the beach sands mineral mix is evenly fed via a vibratory feeder onto a conveyor belt which passes under all three magnetic discs. Each magnetic disc produces a different magnetic force to separate a specific group of minerals. In addition, each magnetic disc is positioned at a tilt of approximately 1 to 2mm to generate two slightly different magnetic fields at the front and rear of each disc. Subsequently, there are six separate stages of separation.

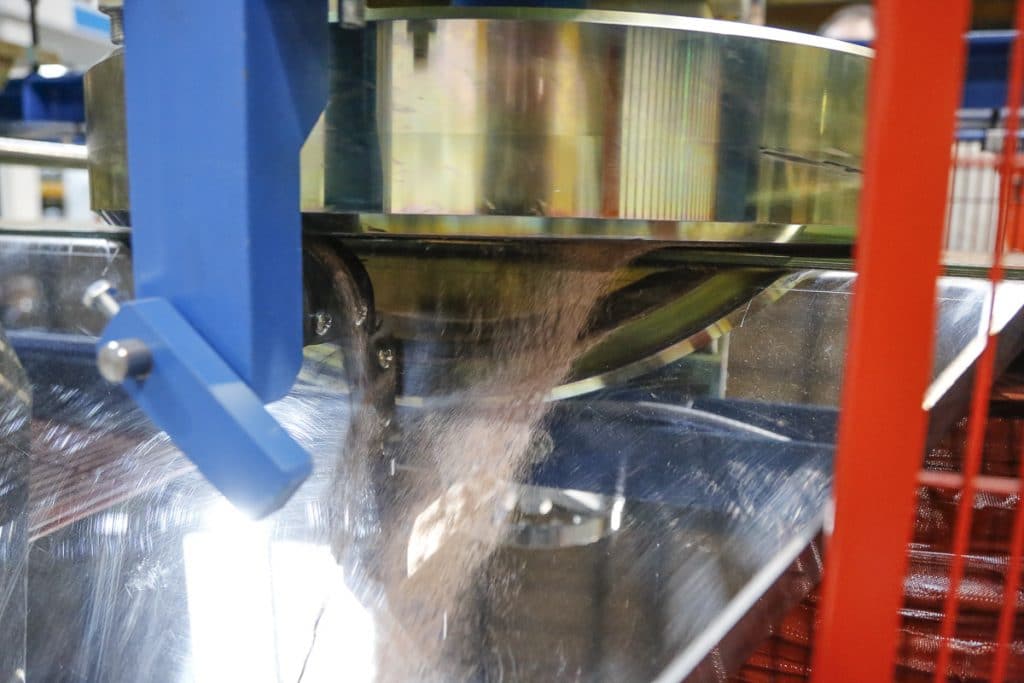

In this beach sands application, disc 1 is set to first produce 7000 gauss on the surface the belt (separation stage 1) and 8000 gauss at the rear (separation stage 2). The mineral mix is conveyed under the clockwise rotating disc with the 7000 gauss magnetic field removing larger iron-bearing particles including the highly paramagnetic ilmenite (FeTiO3) into the first collection area to the left of the feed direction. The black mineral rich fraction is used as a source for TiO2.

The magnetic field strength at the rear of the disc is 8000 gauss and removes any remaining and smaller-sized particles of ilmenite. The combined ilmenite recovery rate from disc 1 is +95%.

Disc 2 is rotating in a counter-clockwise direction to the conveyor feed and focuses on recovering minerals of medium magnetic susceptibility. Separation stage 3 uses a magnetic field of 13,000 gauss to recover pink and red minerals such as Almandine Garnet (Fe3Al2SiO2). At the rear, the magnetic disc is generating a higher field of 14,000 gauss. This recovers any remaining almandine garnet. In this application, the recovered garnet is sized for use as an abrasive grit media in shot-blasting applications.

The third and final magnetic disc rotates in a clockwise direction in relationship to the feed and is set to produce fields of 16,000 (separation stage 5) and 22,000 (separation stage 6). Separation stage 5 is for the recovery of the weakly paramagnetic orange-brown mineral monazite ((Ce,La,Nd,Th)PO4) with stage 6 recovering smaller monazite particles. Through the two separation stages recovery is +95%. Monazite is a phosphate mineral that contains rare earth elements; in this case the minerals include Neodymium, Cerium, Lanthanum and Praseodymium. The mineral is a highly valued raw material source for rare earth magnet manufacture.

The remaining non-magnetic, cream-coloured mineral fraction is a mix of silica sand, rutile and zircon sand, which is separated using electrostatics, froth flotation and density separation. Rutile is used in the production of tioxide (via the Chloride route); zircon sand is commonly used in ceramics; and silica sand is the base material in the manufacturing of glass and ceramics.

The ability of the Magnetic Disc Separator to produce six different fractions from one source makes the technology ideal and unique for many applications. Presently, Bunting is manufacturing a number of Magnetic Disc Separators every year, as well as undertaking numerous tests in their mineral processing laboratory.

The Magnetic Disc Separator is one of several specialist high-intensity magnetic separators in Bunting’s mineral processing portfolio.

Related Mineral Processing Technical Articles

Magnetic Separators – Mineral Processing Laboratory

Bunting-Redditch has one of the most comprehensive magnetic separation mineral processing testing laboratories in the world. Their Laboratory Technicians have decades of experience in mineral processing. Controlled tests ensure that the most suitable and cost-effective machinery is recommended for each application. The laboratory is equipment with a wide range of equipment including:

- Smaller scaled versions of industrial Magnetic Separators. This equipment is used to accurately scale up to industrial capacities and calculate performance guarantees;

- X-Ray Fluorescence and X-Ray Diffraction analysis are available for chemical assay and mineralogical identification to aid the development of a viable process route for each application;

For further information on our range of magnetic separation equipment designed for purifying ceramics and non-metallic minerals, or to arrange sample tests in our laboratory, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

All photographs and video taken by Paul Fears Photography

To keep up to date with our news and technical reports, please follow us on social media