Separating Fine Iron from Powders

By Paul Fears | 06 May 2020

Effectively separating fine iron from dry powders is often challenging. Even the strongest magnetic separator may fail to successfully remove the magnetic particles. In order to find a successful solution, it is important to understand the way fine materials behave. Only then is it possible to determine the optimum method to cleanse a powder of problematic fine iron.

What is a Powder?

Dry powders are used in a wide variety of industries including food, pharmaceuticals, refractories, and chemicals. It is estimated that 80% of materials used in industry are in a dry powdered form.

A ‘powder’ is defined as fine dry particles produced by the grinding, crushing, or disintegration of a solid substance. The handling and processing of powders is often challenging as bulk powders exhibit similar properties to both solids and liquids.

Metal Contamination

The introduction of metal contamination, commonly in the form of iron, occurs at any stage within a powder process. If larger tramp metal (e.g. nails, nuts, rust, etc) remains undetected it enters the size reduction stage. Such tramp metal often damages process equipment, with magnetic separators and metal detectors installed to capture and remove the metal. If passing through this stage, the tramp metal becomes significantly reduced in size and, subsequently, increasingly difficult to extract.

Magnetically susceptible metal contamination (i.e. iron) is commonly removed using magnetic separators. Although there are Magnetic Separators where the magnetic field is produced with an electrical current, the vast majority utilize permanent magnets such as Ceramic Ferrite and Rare Earth Neodymium Iron Boron (Neodymium). Ceramic Ferrite Magnets produce low strength but deep magnetic fields, while Neodymium Magnets create the strongest permanent magnetic presently commercially available.

What is the Origin of the Metal Contamination?

Metal contamination in bulk powders commonly originates from:

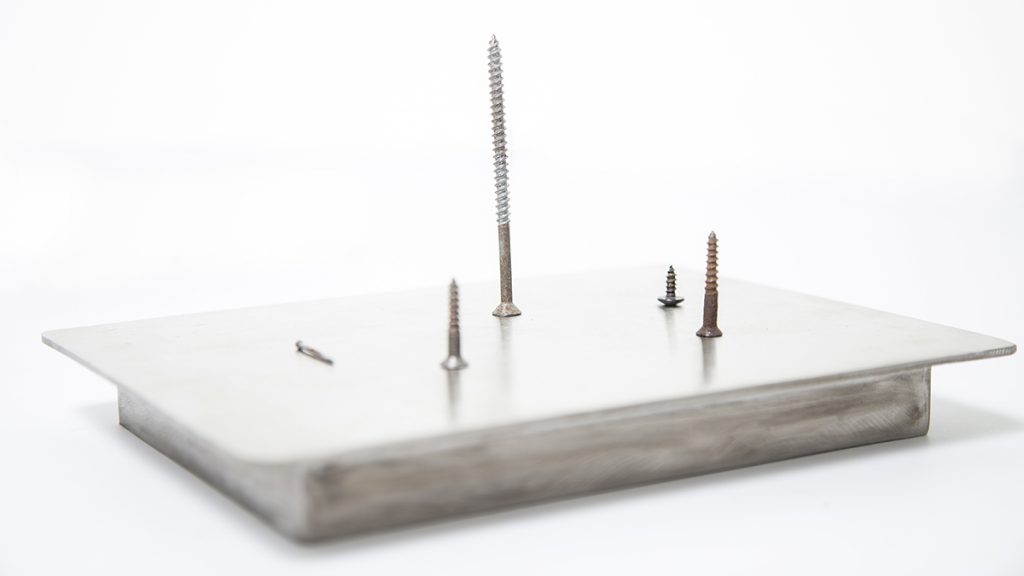

- Primary large tramp metal, such as a nail, screw or bolt;

- Primary fine iron or magnetic particles that are present in the raw material. This originates from primary processing, transportation, or even naturally occurs in the original material;

- Secondary fine iron originates from a larger item of tramp metal (i.e. primary large tramp iron) that has been reduced in size during the powder manufacturing process. Typically, this could be from a nail, screw or bolt that has been through a crusher or from damaged or worn processing equipment. Another common source of secondary fine iron contamination is rust, falling into the process from weathered and worn processing equipment such as chains, hoists, and building cladding.

The separation and detection of tramp metal is easier when the metal contamination is in a larger form and can be successfully removed using a wide range of suitable Magnetic Separators and Metal Detectors. Magnetic Separators using standard strength Ceramic magnets, with deep magnetic fields, are ideal. A good example is the Plate Magnet, often installed in a chute, in a housing, or as part of an In-Line Magnetic Separator.

Metal Detectors remove Larger Metal

Larger metal contamination is also easier to detect on a Metal Detector. Metal is detected as it passes through the coil of the Metal Detector and an automatic reject system removes it from the flow. For detection, the magnetic field generated by the Metal Detector has to see a state change. Finer sized metal produces a lesser state change and thus increases the difficulty in detection.

quickTRON Metal Detector

In a project in Pakistan, a processor of fine Sodium Bicarbonate is using a QuickTRON Metal Detector to remove the larger tramp metal.

Removing larger tramp metal with a Magnetic Separator and Metal Detector prior to the processing stage not only prevents the metal from being reduced in size (e.g. converted into a secondary source of fine iron contamination), but also protects delicate processing equipment such as crushers, shredders, and mills from being damaged by the metal.

Once in a powder form, there are important processing parameters to consider when assessing the optimum method to remove fine iron contamination.

Magnetic Separators for Fine Iron Removal

When a powder is sprinkled, it remains light and free. However, when the same powder is vibrated or compressed, it may become very dense and even lose the ability to flow.

Individual grains in bulk powders cling to each other in clumps, in accordance with the Van der Waals force. This coagulation often results in the fine iron being trapped in among clean product. The ability of any Magnetic Separator to attract, hold and separate the fine iron is dependent on the iron being as close to the magnetic field as is physically possible. If the fine iron contacts the surface of a Magnetic Separator with a high strength magnetic field, it will be held. However, when the fine iron is held inside a coagulation of powder, then it could be held out of the reach of the maximum magnetic force. Thus, it will not be separated.

The way bulk powders flow impacts on the design of the Magnetic Separator. Powders flowing in a hopper may experience classic flow problems such as ratholing, bridging or flooding, all of which could be exacerbated by the design of Magnetic Separator.

Different Designs of Magnetic Separator

High strength magnetic fields, as produced by Rare Earth Neodymium Magnets, are needed to capture fine iron metal contamination. There are four main magnet configurations suitable for handling powders.

- Tube Magnets (also known as Rod Magnets and Cartridge Magnets), often in a multi-rod Grate configuration;

- Flat-faced Plate Magnets;

- Cone-shaped Bullet Magnets housed inside a tubular body;

- Drums Magnets with a fixed curved magnetic arc positioned inside an independently rotating outer shell;

- Electromagnetic Dry Filter which uses high-intensity magnetic field to capture fine magnetic particles, especially in high value powders;

Tube, Grate and Drawer Filter Magnets

Although occasionally a Tube Magnet may be used on its own, it is more commonly part of a larger multi-cartridge Grate system. The Magnetic Grate is designed to fit inside a hopper, or can be supplied complete with a housing (i.e. as a Drawer Filter Magnet).

In operation, powder falls freely onto the surface of the Tube Magnet where fine iron strikes the surface and is held by the strong magnetic field. To ensure that the powder makes contact with the Tube surface, deflectors are often deployed above the gaps between the Tubes.

Powder build-up on the surface of a Tube Magnet will reduce the separation efficiency. Also, in severe cases, a slight build up on the surface of the Tube may quickly cause a blockage of the whole housing.

Such blockages can be prevented by ensuring that there is optimum space between the Tube Magnets. Also, in some cases, the mounting of an external vibrating motor on the side of the hopper or housing will provide enough disturbance to prevent any material coagulation. The frequency of the vibration needs careful consideration as it could affect the flow ability of the powder. Additionally, when vibrators are used, the Tube Magnets need to be manufactured to withstand prolonged periods of vibration.

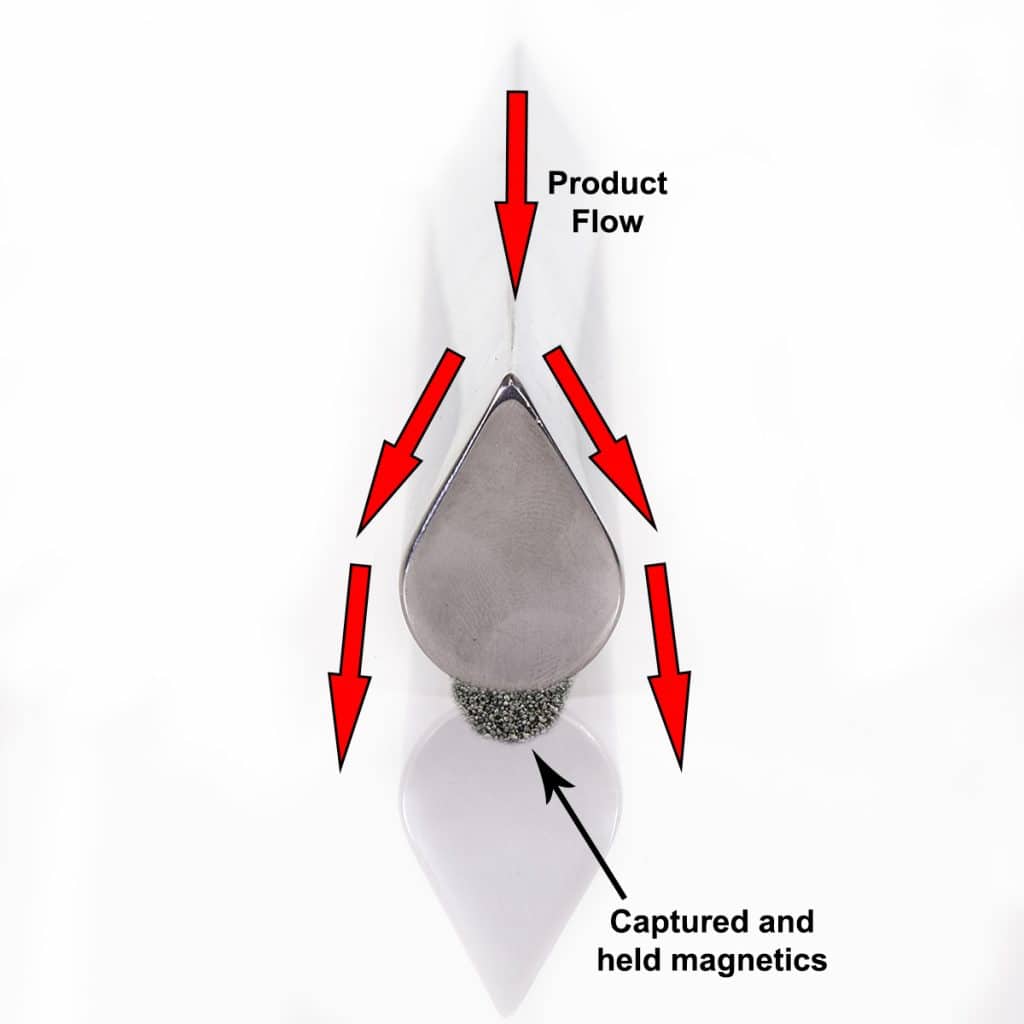

‘Teardrop’ shaped Tube Magnets are specifically designed to stop the build-up of fine powder on the surface. The sharp edge of the teardrop faces up into the product flow and allows material to flow around the edge and into the magnetic field. Magnetic particles are captured and held underneath the Tube Magnet.

Plate Magnets

Flat-faced Plate Magnets are ideal when it is possible for the material to flow over the surface. Rare Earth Neodymium Plate Magnets capture finer iron. This magnetic field is further enhanced when a Tapered Step is added to the face of the magnet. Captured iron migrates behind the step and away from the material flow, reducing the risk of re-entering the cleansed product.

In-Line Magnets

As well as being fitted into chutes, Plate Magnets are incorporated into housings as In-Line Magnets. In-Line Magnets remove tramp iron and ferrous fines from flow-resistant bulk powders without restricting the flow. There are two designs:

- Gravity In-Line Magnets (GIM) – The Plate Magnets are positioned in round, sloping spouting where material is under gravity flow. For effective tramp metal capture, the spouting should be angled no more than 60° from horizontal;

- Pneumatic In-Line Magnets (PIM) – These designs are for use in dilute phase pneumatic conveying systems (up to 15psi). They can be installed easily with optional factory-supplied compression couplings and work best in horizontal runs with the plate magnet down to take advantage of material stratification;

Bullet Magnets

The Bullet Magnet is widely used in the bulk handling industry and features a centrally located ‘bullet’ shaped magnet inside a tubular housing. The positioning of the Magnetic Cone allows powder to flow without obstruction.

The conical magnet is suspended in the center-line of the housing to ensure maximum contact with the product flow. This tapered, exposed-pole magnet has a stainless steel “nose cone” to direct the flow of materials around the magnet. The tapered poles of the cone magnet allow ferrous fines to collect out of the direct air stream. Additionally, the trailing end of the magnet is an active magnetic pole and holds any tramp metal that is swept down the cone.

Drum Magnets

In specific applications, a high strength Permanent Drum Magnet enables the optimum level of separation. The Drum Magnet is gravity-fed, usually via a Vibratory Feeder. The Drum Magnet has a stationary high-strength magnetic arc positioned inside a rotating outer shell. When material flows onto the drum magnet, the magnetic field projected by the stationary magnetic assembly inside the shell attracts and holds fine iron securely to the drum’s stainless steel surface. With contaminants captured, the cleansed product falls freely to a discharge point. As the drum rotates, the captured fine iron travels along the drum surface and out of the magnetic field, where it is discharged.

There are various magnetic field configurations possible, but the most suitable for removing iron from bulk powders is one that produces a Radial Magnetic Field. This ensures that once captured, the fine iron does not leave the Drum surface until it moves out of the magnetic field.

The ‘Wire Wrapped’ Drum Magnet design enhances the intensity of the magnetic field to separate weak magnetic particles and para magnetic minerals.

There are several challenges to overcome when processing bulk powders on a Drum Magnet.

Feeding the Drum Magnet

It is recommended that the Vibratory Feeder has an air bed to produce a consistent feed of powder. Standard Vibratory Feeders may deliver powder in clumps, significantly affecting the separation performance;

Drum Shell Rotating Speed

The shell of the Drum Magnet should be rotated at high speeds. This will result in some of the powder pluming, and this can be minimized by keeping the distance between the end of the Vibratory Feeder Tray and the rotating surface of the Drum Magnet to a minimum.

The high rotation speed of the Drum Magnet significantly reduces the amount of product lost to the magnetics. This is because there is less material on the surface of the Drum at any one time, reducing the chance of entrapment.

The use of Drum Magnets operating at high rotational speeds has been very successful in removing fine iron from abrasives, refractories, and other applications where the material has a high specific gravity.

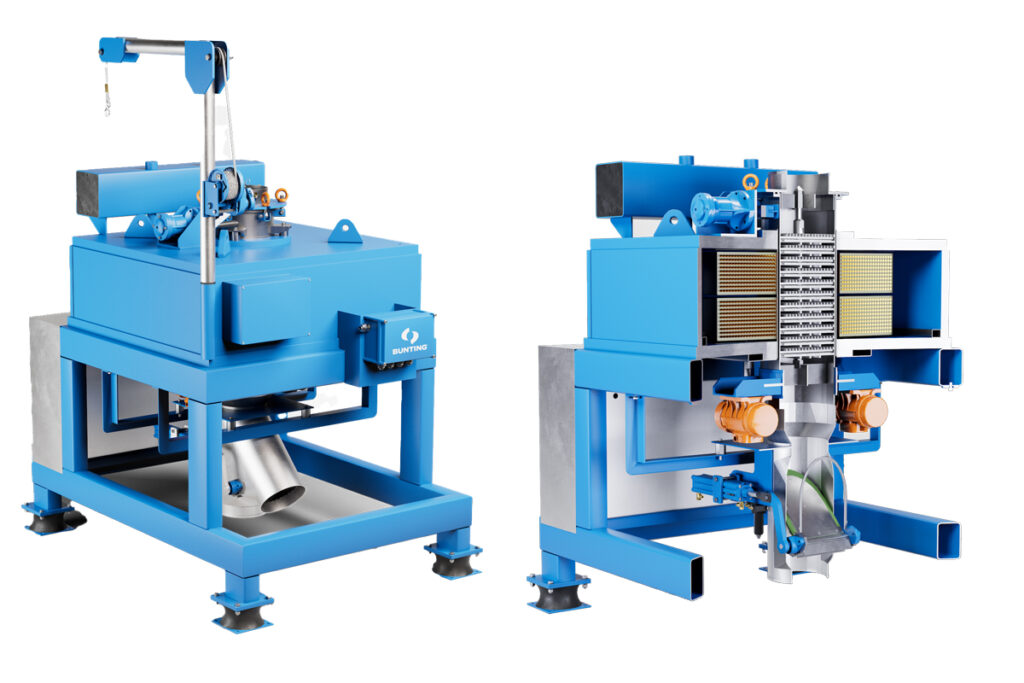

Electromagnetic Dry Filter

This high-intensity magnetic separator generates ultra-strong magnetic fields to capture ferrous particles present in difficult-to-process fine materials. The new technology enhances magnetic separation in a diverse range of applications found in mineral processing, chemical and pharmaceutical production, ceramics, and recycling.

The Electromagnetic Dry Filter features a centrally-located vibrating canister inside a specially designed electromagnetic coil. The coil generates between 3,500 and 5,000 gauss in the canister, which is then concentrated on the points of the matrix to reach peaks of up to 12,000 gauss.

In operation, fine powder flows under gravity through the vibrating canister which is packed with magnetic stainless-steel matrix. Magnetic particles are attracted to the magnetically induced matrix and held until the batch feed is stopped. The electromagnet is then turned off, releasing the magnetic particles into a separate waste collection area, before processing is resumed.

The Electromagnetic Dry Filter is particularly suited for the magnetic particle purification of high-value fine powders, especially when processed and produced in controlled batches.

Magnetic Separators and Metal Detectors for Powder Purification

For additional information on any of the Magnetic Separators or Metal Detectors mentioned in this article, please click on the links below:

- Tube and Grate Magnets

- Drawer Filter Magnets

- Plate Magnets

- In-Line Magnets

- Bullet Magnet

- Drum Magnets

- Electromagnetic Dry Filter

- Metal Detectors

Ensuring Bulk Powders are Metal-Free

As the demand for finer and purer powders increases, so does the need to remove even the finest iron. Understanding the properties and behaviour of the powder is vitally important when considering the optimum method of fine iron separation. Often the ultimate solution is a series of Magnetic Separators and Metal Detectors located at strategic points within the process. Bunting’s engineers provide free onsite advice to determine the optimum solution for any process.