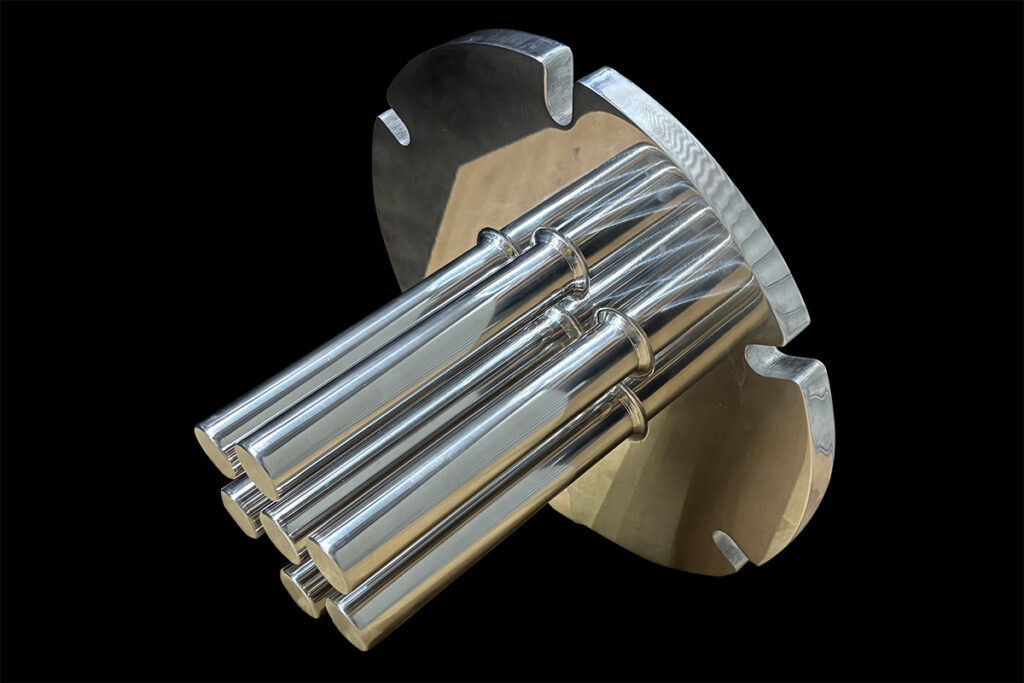

Tube Magnet

Chocolate Safety with Liquid Magnetic Separators

A UK chocolate conche manufacturer has purchased five (5) Bunting Liquid Magnetic Separators to capture ferrous metal contamination generated during the chocolate manufacturing process. Conching is a key part of chocolate making involving the continuous mixing, grinding, and kneading of chocolate mass over a prolonged period. The conche is a machine specifically designed for the…

Read MoreNecessity of Cleaning Magnetic Separators

When on site, our Technical Sales Engineers often take opportunity to check the installed magnetic separators. At many sites, this results in a conversation about the required cleaning frequency for a permanent magnetic separator such as a Drawer Filter Magnet, Plate Magnet, or Liquid Magnetic Separator. This is when captured ferrous metal is manually removed…

Read MoreHigh-Intensity Magnetic Separation at Ceramitec 2024

High-intensity magnetic separators reduce rejects, rework, and increase ceramic whiteness. On Bunting’s stand A6 323D at Ceramitec 2024 (9-12 April, Munich, Germany), ceramic engineers and ceramic mineral processors can find out about the latest high-intensity magnetic separation technology for both wet and dry processes. Keeping Ceramic Glazes, Slips and Bodies Free of Magnetics Fine iron…

Read MoreProtection Against Metal Contamination at Interpack 2023

Magnetic separators, metal detectors and x-ray foreign body detectors to identify and remove metal and other contamination prior to and after packing are the focus for Bunting at Interpack 2023 (4-10 May, Düsseldorf, Germany). On stand D66 in hall 11, Bunting will exhibit working metal separators such as high-strength rare earth Drawer Filters Magnets; conveyor-mounted…

Read MoreMetal In Food Alerts 2022

In 2022, the UK Food Standards Agency issued ten (10) alerts regarding metal-contaminated food products that had reached the public. This was up from five (5) in 2021. The metal-contaminated food products were supplied by companies at various stages in the food supply chain, including leading UK supermarkets such as Tesco and Co-Op, as well…

Read MoreSeparating Problematic Metal at POWTECH 2022

At POWTECH 2022 (27-29 September, Nuremberg, Germany), Bunting’s focus is on the separation of problematic metal from dry materials. On stand 3A-613, visitors will see the latest magnetic separators and metal detectors that effectively remove tramp metal and very fine iron from a wide range of granules and powders. POWTECH is the leading European trade…

Read MoreTemperature Effect on Magnetic Separators

If a Neodymium Rare Earth Tube Magnet is put into a red-hot fire, then it would not be surprising if the magnetic properties are destroyed. However, what if the same Tube Magnet is just exposed to steam being flushed through a pipeline system to clean the pipes? Tube Magnets manufactured with high quality Neodymium Magnets are able to…

Read MoreHigh-Intensity Magnetic Separators at Ceramitec

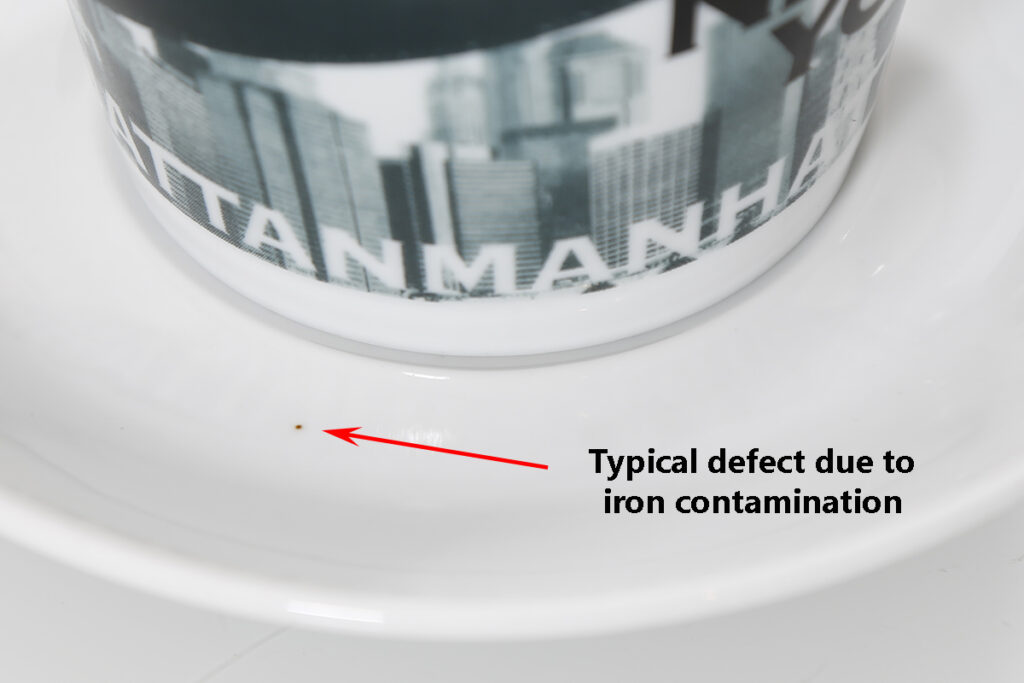

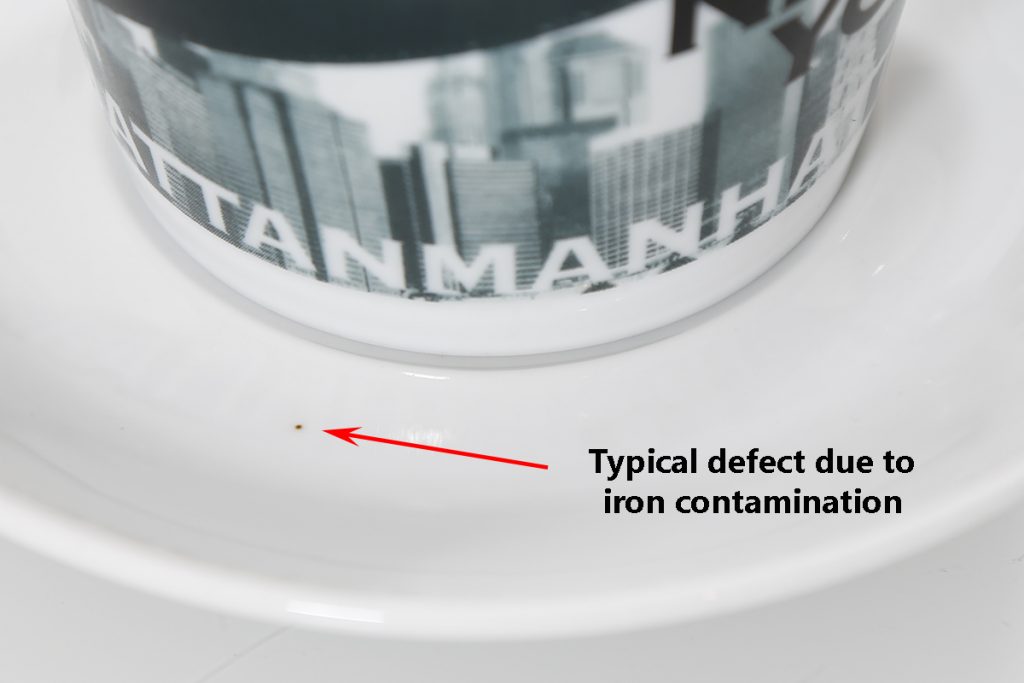

High-intensity magnetic separators play a key role in the manufacture of ceramics and the processing of ceramic raw materials, as highlighted at Ceramitec 2022 on Bunting’s stand (on stand C1:511). Keeping Ceramics Iron-Free Fine iron and magnetic minerals cause defects in any ceramic product, whether that is tableware, sanitaryware, tiles or technical ceramics. The iron…

Read MoreMagnetic Separator Air-Gap Explained

The ‘Air Gap’ plays a key role in the performance of a Magnetic Separator. In all magnetic separators, there is a gap between the magnet material or electromagnetic coil and the targeted particle. This ‘air-gap’ could be actual air or a non-metallic material such as stainless-steel or a rubber belt. When assessing an application, our…

Read MoreFive Magnetic Separator Myths

Often ascertaining the best Magnetic Separator for any given application is not straightforward. To complicate the decision-making process further, many companies supplying magnetic separators provide a wealth of information such as Gauss levels and the amount of metal that the Magnetic Separator can actually capture. Such details are often difficult to verify and may even be meaningless. In this…

Read More