New XRF Enhances Mineral Testing Capabilities

By Paul Fears | 22 July 2019

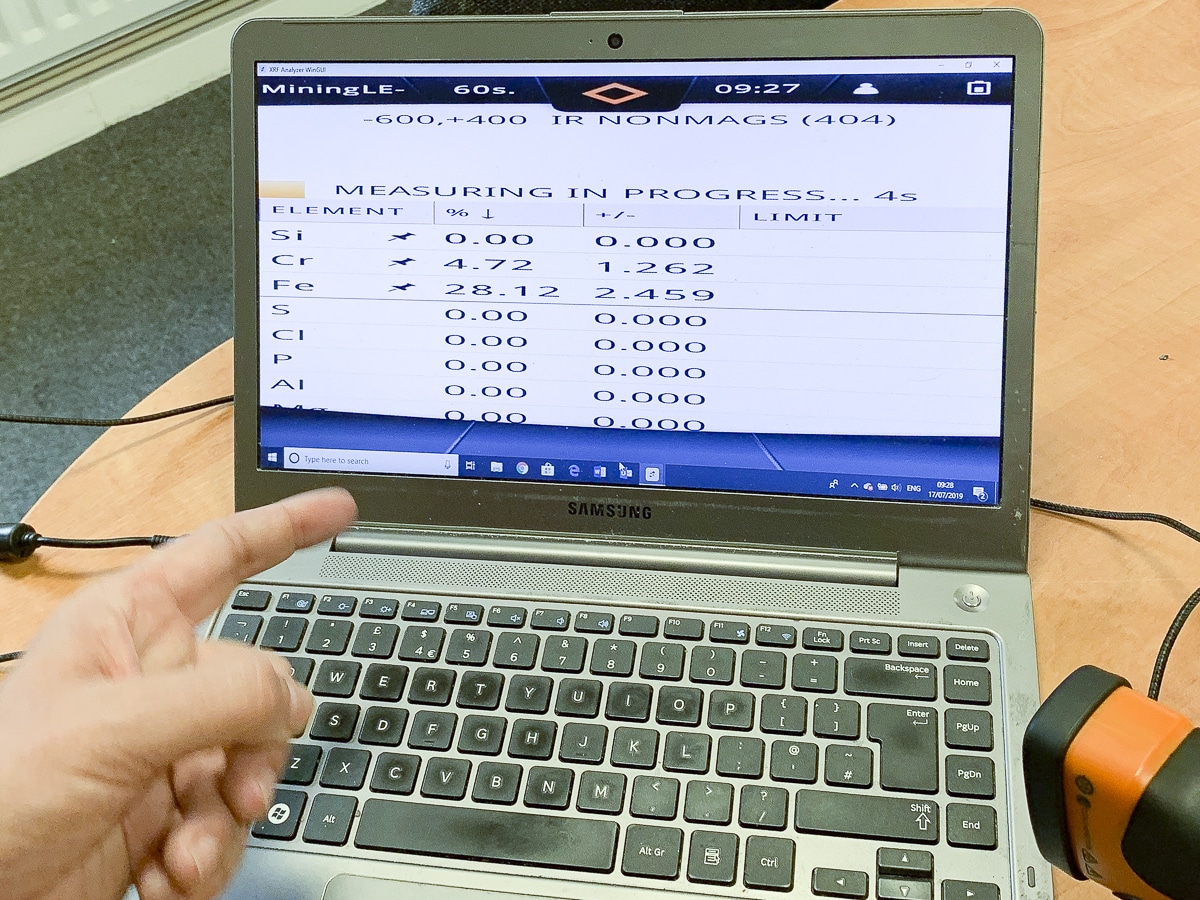

The purchase of a new X-ray fluorescence (XRF) analyser enhances the mineral testing capabilities of the Bunting test laboratory based at the manufacturing facility in Redditch, UK. Hitachi High-Tech Analytical Science, based in Abingdon, UK, supplied the X-MET8000 Expert XRF analyser and provided comprehensive training for the technical staff at Bunting.

The Science of X-Ray Fluorescence

X-ray fluorescence (XRF) is the emission of characteristic secondary (or fluorescent) X-rays from a material that has been excited by being bombarded with high-energy X-rays or gamma rays. The phenomenon is widely used for elemental analysis and chemical analysis, particularly in the investigation of minerals, metals, glass, ceramics, and building materials.

The Hitachi High-Tech Analytical Science X-MET8000 range of handheld X-ray fluorescence (HHXRF) analysers enables rapid alloy grade identification and accurate chemistry of a wide variety of materials (including solid and powder metals, polymers, solutions, ores, and minerals).

The purchased X-MET8000 is custom-made to provide complete chemical analysis of mineral and soil samples tested in the Master Magnets laboratory facility. Extra analysis packages allow for the assay of rare earth metals in mineral deposits, which are a major commercial interest to mining houses. The X-MET provides great light elements (Mg, Al, Si, P, S, Cl) analysis, thereby providing a comprehensive analysis tool for most mineral development projects.

The additional metal alloy package makes it suitable for analysis of metal fractions from waste recycling applications. This is ideal when conducting tests on the Eddy Current Separator and Stainless Steel Separator in the recently built recycling test facility.

In practice, the new XRF enables the quick and efficient evaluation of separated fractions. Such immediate analysis leads to fine adjustment of the equipment to maximise the separation performance. Once the tests are completed, the technicians make detailed and accurate recommendations on the design of the magnetic separator, the operating criteria, and the separation performance.

“This latest investment in our test facility means we are able to provide our customers with a more complete service,” explained Adrian Coleman, the Bunting-Redditch General Manager. “Many projects are time-critical and our ability to analyse the materials in-house significantly shortens the testing process, whilst enabling our technicians to fine-tune the equipment to maximise the separation performance.”

Related Mineral Processing Technical Articles

Magnetic Separators – Mineral Processing Laboratory

Bunting-Redditch has one of the most comprehensive magnetic separation mineral processing testing laboratories in the world. Their Laboratory Technicians have decades of experience in mineral processing. Controlled tests ensure that the most suitable and cost-effective machinery is recommended for each application. The laboratory is equipment with a wide range of equipment including:

- Smaller scaled versions of industrial Magnetic Separators. This equipment is used to accurately scale up to industrial capacities and calculate performance guarantees;

- X-Ray Fluorescence and X-Ray Diffraction analysis are available for chemical assay and mineralogical identification to aid the development of a viable process route for each application;

For further information on our range of magnetic separation equipment designed for purifying ceramics and non-metallic minerals, or to arrange sample tests in our laboratory, please contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

To keep up to date with our news and technical reports, please follow us on social media