Posts Tagged ‘High Intensity Magnetic Separation’

Bunting Speaking at UK Mining Conference

Bunting Magnetics’ Applications Engineer, Michael Allen, is explaining the important role of magnetic separation in mining and mineral processing at the UK Mining Conference in Cornwall (11-12 June 2025, Falmouth, UK). The two-day conference brings together professionals from the global mining and mineral processing community. Valuable Mineral Processing Experience At the conference, Michael is joined…

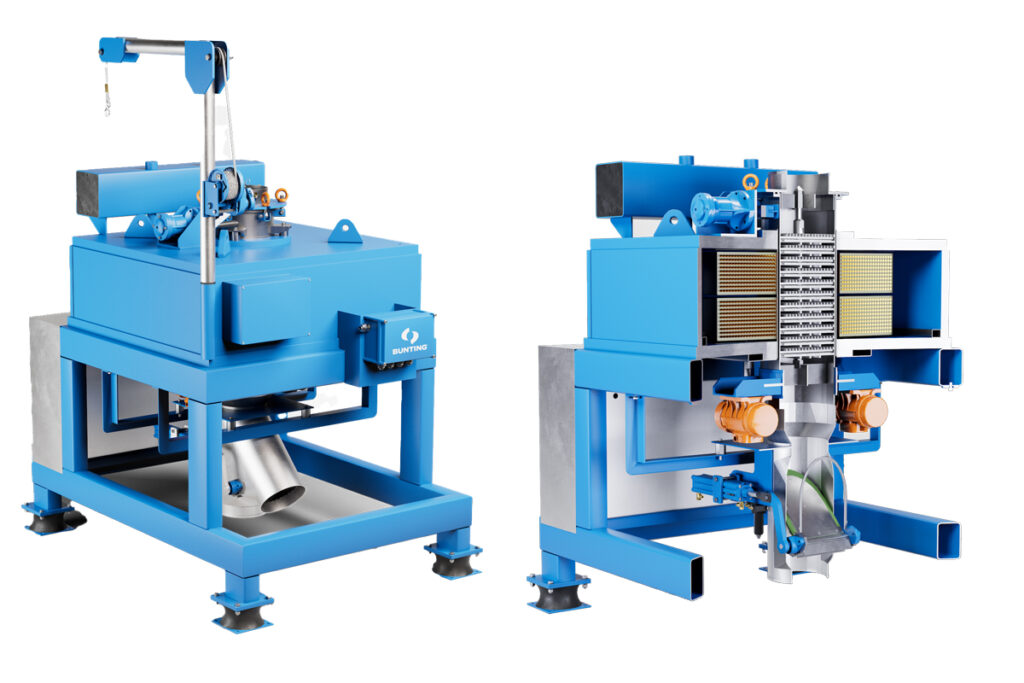

Read MoreBunting Develops High-Intensity Electromagnetic Dry Filter

Bunting has developed a new Electromagnetic Dry Filter to remove free fine iron from powders. The high-intensity magnetic separator generates ultra-strong magnetic fields to capture ferrous particles present in difficult-to-process fine materials. The new technology enhances magnetic separation in a diverse range of applications found in mineral processing, chemical and pharmaceutical production, ceramics, and recycling.…

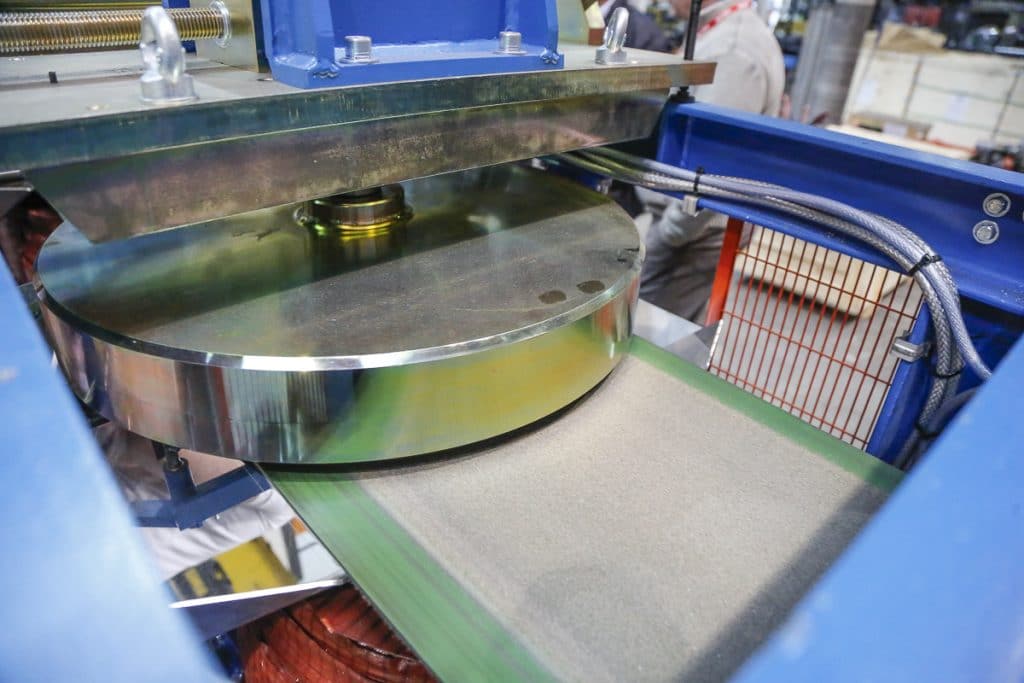

Read MoreBunting Develops High-Intensity Electromagnetic Wet Filter

Bunting has developed a new Electromagnetic Wet Filter with an ultra-high-intensity, background magnetic field (from 3,500 up to 10,000 Gauss). The magnetic separation technology separates fine iron and paramagnetic minerals from liquids and slurries and is used in the ceramics, mineral processing, and recycling industries, as well as cleaning wastewater in steel production and power…

Read MoreHigh Intensity Magnetic Separation at UK Mining Conference

High intensity magnetic separation and enhanced tramp metal magnetic separation is the focus for Bunting at the UK Mining Conference in Cornwall, UK (12-13 June 2024). High-profile delegates including investors, brokers, operators, and the mining supply chain attend the two-day conference, held at the historic Princess Pavilion in Falmouth in Cornwall. The recent rise in…

Read MoreLaboratory High-Intensity Magnetic Separator for Battery Recycling Research

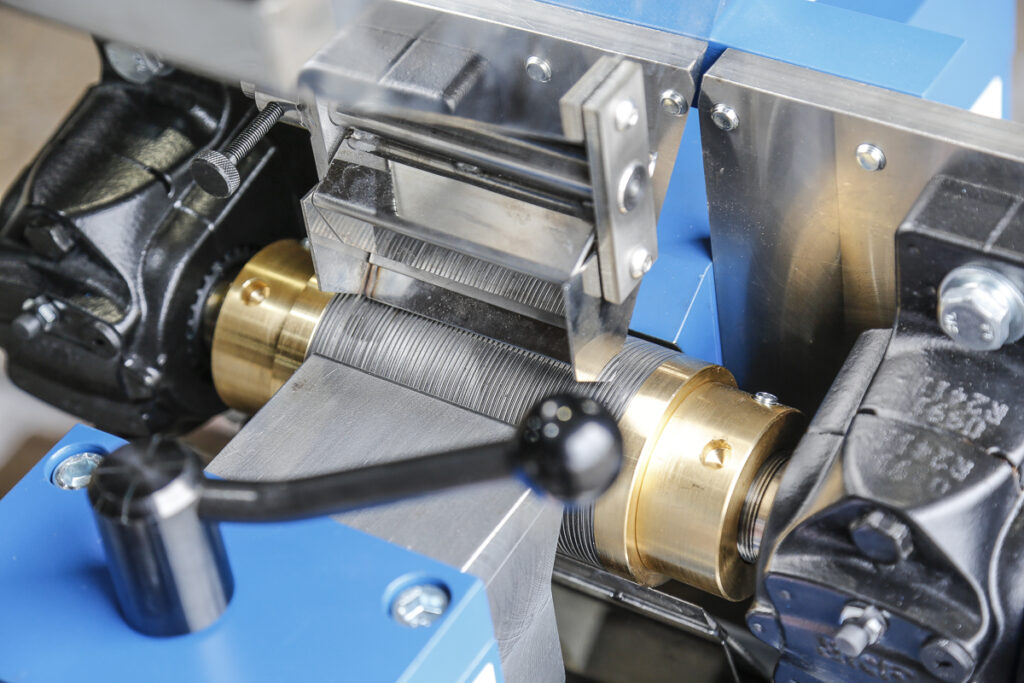

A European mining and technology university has purchased a laboratory-scale Bench Induced Roll Magnetic Separator (BIRS) for use in research projects including the recycling of lithium-ion batteries. The BIRS generates high-intensity magnetic fields up to 2 Tesla (20,000 Gauss), enabling the separation of weakly magnetic particles. The Induced Roll Magnetic Separator (IRS) The Induced Roll…

Read MoreIlmenite Producer Purchases Magnetic Disc Separator

A European Ilmenite producer has purchased a 2-stage Magnetic Disc Separator (MDS). The mineral processor originally purchased their first Magnetic Disc Separator in 1995. The new magnetic separator will provide additional processing capacity as well as guaranteeing continual production. The mineral ilmenite (FeTiO3) is mined for the production of titanium dioxide, which is commonly used…

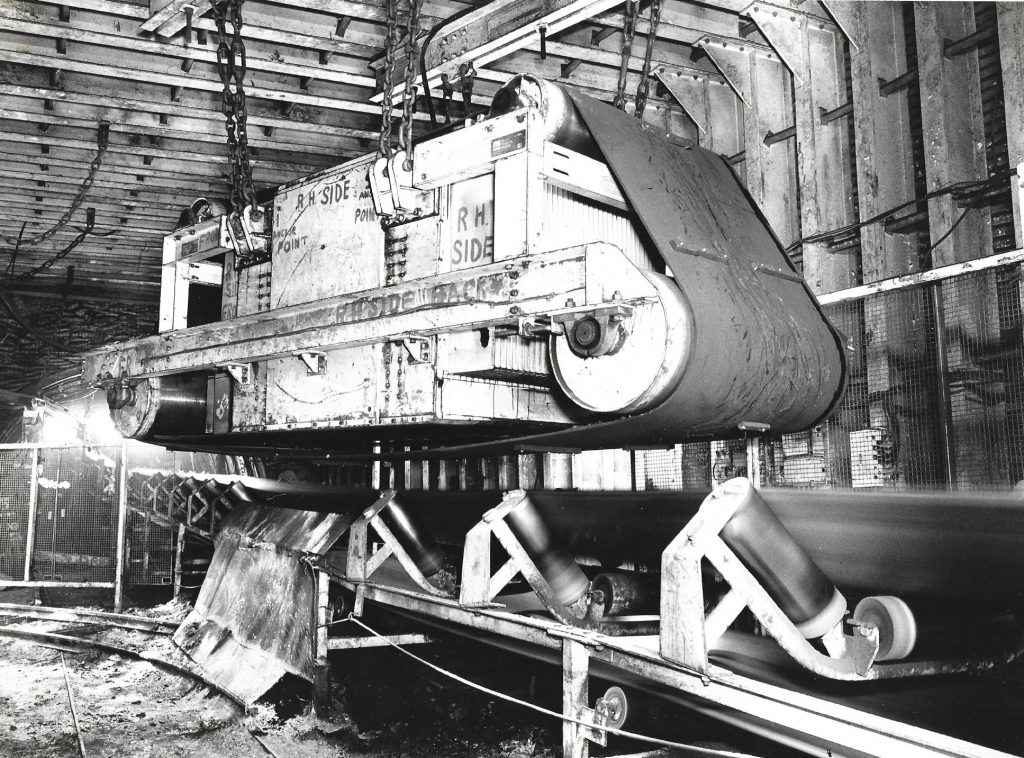

Read More30 Year Magnetic Separator Market Evolution

Our Press Officer, Paul Fears, first became involved in marketing magnetic separators in 1989. In this blog, Paul looks back at the evolution of the magnetic separator market. When I started my career in 1989, I had no comprehension of the importance of magnetic separators. I quickly discovered that the technology was used in every…

Read MoreElectromagnetic Filters for Ceramics

Since the first ceramics were produced, iron and iron-bearing minerals have caused defects. The problematic minerals occur naturally in the raw materials, with additional fine iron accidentally introduced during transportation, storage or processing. Effective removal often involves several stages of magnetic separation. However, the introduction of High-Intensity Electromagnetic Filters proved ground-breaking in terms of removing…

Read MoreWet High Intensity Magnetic Separation Testing

The electromagnetic laboratory-scale Wet High Intensity Magnetic Separator (WHIMS) removes fine magnetics and para-magnetics from mineral slurries. Handling minerals in a slurry or suspension is preferable for many processors, especially when beneficiation involves wet processing. Additionally, a wet process often produces a better separation for very fine materials. In this educational video, Professor Neil Rowson…

Read More