Posts Tagged ‘Magnetic Separator’

Five Magnetic Separator Myths

Often ascertaining the best Magnetic Separator for any given application is not straightforward. To complicate the decision-making process further, many companies supplying magnetic separators provide a wealth of information such as Gauss levels and the amount of metal that the Magnetic Separator can actually capture. Such details are often difficult to verify and may even be meaningless. In this…

Read MoreThe Crusher’s Arch Enemy – Tramp Metal

Crushing quarried aggregate is a key process stage of most quarries and when recycling demolition waste. Effectively protecting the crusher from rogue tramp metal damage prevents production losses and repair costs. The wide range of available crushing technology enables the production of optimally sized aggregate. Whereas Jaw and Gyratory designs commonly feature as primary crushers,…

Read MoreElectromagnetic Filters for Ceramics

Since the first ceramics were produced, iron and iron-bearing minerals have caused defects. The problematic minerals occur naturally in the raw materials, with additional fine iron accidentally introduced during transportation, storage or processing. Effective removal often involves several stages of magnetic separation. However, the introduction of High-Intensity Electromagnetic Filters proved ground-breaking in terms of removing…

Read MoreRecycling Growth Dependent on Technology

Annual events such as the UK’s Recycling Week, the Global Recycling Day and Earth Day provide the perfect platform for reflection and planning. Successful and extensive recycling reduces the pressure on the planet’s finite resources, whilst also providing desperately needed environmental protection. Many experts predict that the failure to radically change the way waste is…

Read MoreMagnetic Properties of Ceramic Minerals

Magnetic minerals and fine iron have plagued ceramic producers since the first glazed pot was produced many thousands of years ago. Early ceramicists adopted elaborate and colourful patterns to cover any imperfections caused by such contamination. Over time, the demand for white or single coloured ceramic products increased, making disguising any imperfection increasingly difficult. Ceramic…

Read MoreWet High Intensity Magnetic Separation Testing

The electromagnetic laboratory-scale Wet High Intensity Magnetic Separator (WHIMS) removes fine magnetics and para-magnetics from mineral slurries. Handling minerals in a slurry or suspension is preferable for many processors, especially when beneficiation involves wet processing. Additionally, a wet process often produces a better separation for very fine materials. In this educational video, Professor Neil Rowson…

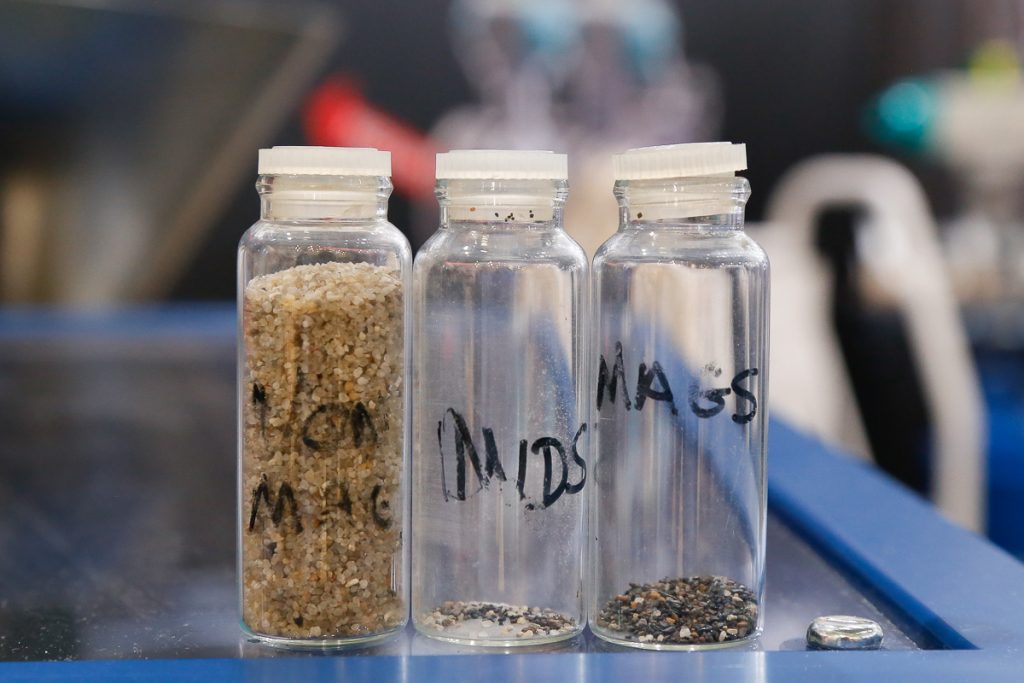

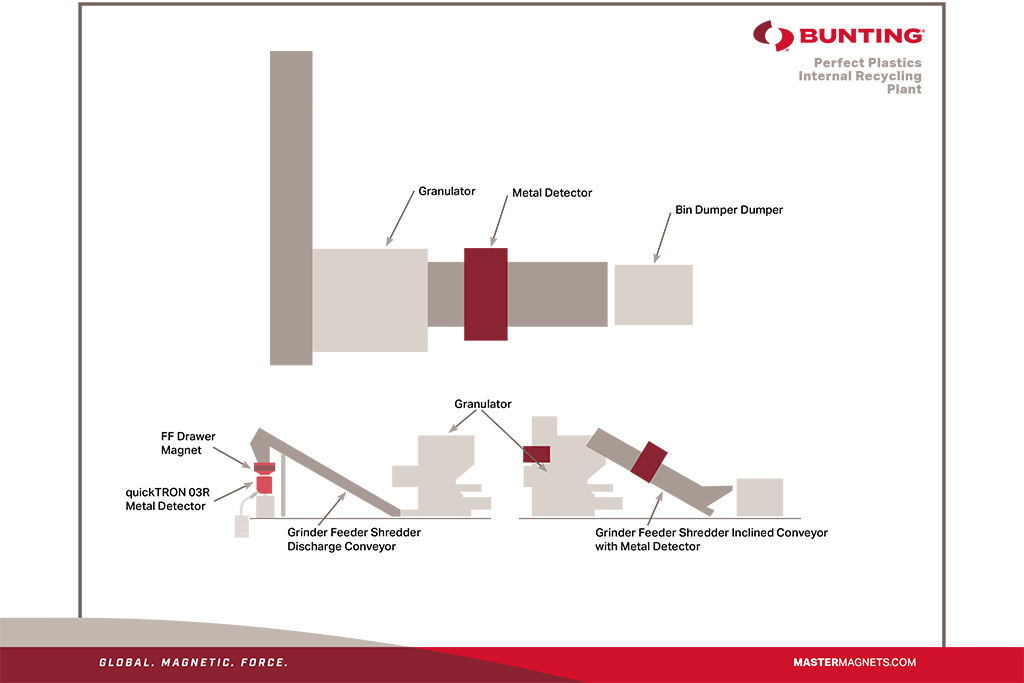

Read MoreEnsuring In-House Plastic Recycling Purity

When re-processing in-house plastic rejects and waste, the purity of the final recycled plastic mix must be equal or at least very close to the original raw material. Whether the re-processed plastic is for in-house use or as regrind for resale, the removal of any metal contamination is critical. Successful removal of metal contamination from…

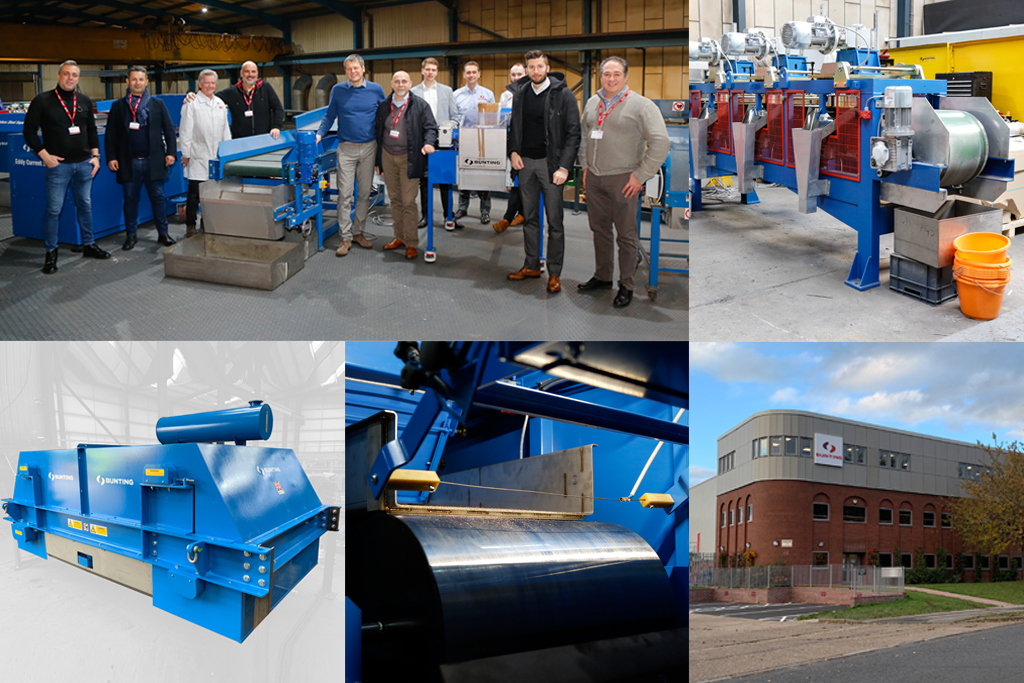

Read MoreBunting-Redditch 2020 Review

To state that 2020 has been challenging would be an understatement. The global Covid-19 pandemic has changed the way people live their lives, and businesses have had to adapt. Despite the difficulties, there has been plenty of positive news coming out of Bunting-Redditch. Throughout 2020, building work has continued on a major plant and office…

Read MoreChute Magnet Separator Checks Magnetic Susceptibility

The Chute Magnet Separator or Magnetic Slide is a simple but important laboratory-scale wet magnetic separator for any material test facility. This magnetic test equipment enables the assessment of a particle’s magnetic susceptibility, which provides the platform for further tests on specific wet magnetic separators. Wet magnetic separation techniques are employed when processing slurries (i.e.…

Read MoreInline Magnets Remove Metal from Potassium Chloride

A UK processor of Potassium Chloride is using two Pneumatic Inline Magnets (PIMS) to capture and remove small tramp ferrous metal. The metal is removed early in the process, as the dry material is being pneumatically conveyed, to prevent damage to processing equipment including the crusher. The two PIMS installed at the Potassium Chloride processing…

Read More