Posts Tagged ‘Magnetic Separator’

Boosted Metal Separation with ElectroMax-Plus Overbands at W Maw

General skip waste recycler W Maw Recycling Ltd has installed two Bunting ElectroMax-Plus Overband Magnets at their Rotherham operation in the United Kingdom. The powerful electromagnetic ElectroMax-Plus Overbands replaced permanent overband magnets to separate larger and heavier ferrous metal that could damage shredders and other process plant. Replacing Permanent Overband Magnets with the ElectroMax W…

Read MoreHigh-Intensity Magnetic Separation at Ceramitec 2024

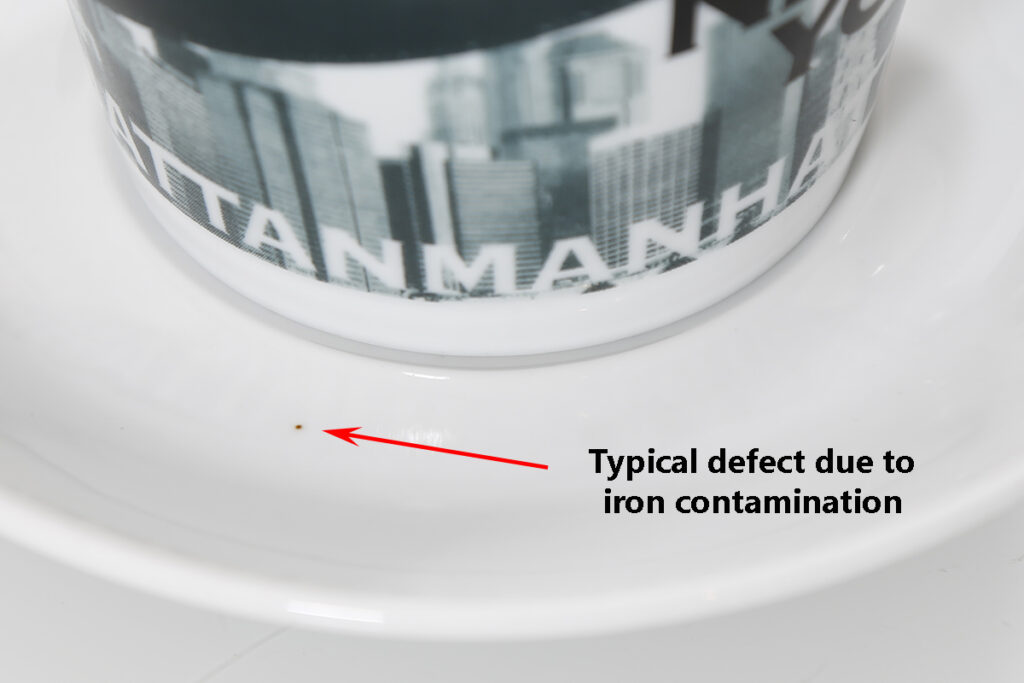

High-intensity magnetic separators reduce rejects, rework, and increase ceramic whiteness. On Bunting’s stand A6 323D at Ceramitec 2024 (9-12 April, Munich, Germany), ceramic engineers and ceramic mineral processors can find out about the latest high-intensity magnetic separation technology for both wet and dry processes. Keeping Ceramic Glazes, Slips and Bodies Free of Magnetics Fine iron…

Read MoreIndustrial Magnetiser Investment for Bunting

To meet the increased demand for magnetic separators following a sustained period of sales growth, Bunting has redesigned and refurbished the industrial magnetiser at their Redditch manufacturing facility in the United Kingdom. The enhancements make this DC impulse industrial magnetiser the largest in the UK, outside of academia. Magnetising Permanent Magnet Assemblies At the Redditch…

Read MoreEnhanced Metal Recovery with Bunting at IFAT 2024

Technology to effectively separate large and small ferrous and non-ferrous metal is the focus for Bunting at IFAT Munich 2024 (Messe Munchen, Germany, May 13-17). Advanced designs of magnetic separators, eddy current separators and electrostatic separators separate strongly and weakly magnetic particles, enabling the successful recycling of a wide range of waste materials. On stand…

Read MoreMBA Polymers Install Quick Clean Drawer Magnet

MBA Polymers has installed a new quick manual-clean magnet insert into one of their existing Drawer Filter Magnets installed at their Worksop plastics recycling operation in the United Kingdom. The new insert significantly reduces the time needed to clean captured ferrous metal off the high-strength tube magnets, whilst also proving easier and safer for operators.…

Read MorePermanent Overband Magnet Selection Criteria

Permanent Overband Magnets are commonplace in most mines and quarries, removing tramp ferrous metal and protecting crushers, screens and conveyors against damage. Overband Magnets are also widely used in recycling, recovering ferrous metals and protecting shredders against metal damage. However, there are many different designs of Permanent Overband Magnet, developed to suit specific applications. Understanding…

Read MoreICL Boulby Upgrades Magnetic Separators

ICL is making significant upgrades to their magnetic separators at their mine in North Yorkshire, England. The company has decided to replace an existing single air-cooled Overband Electromagnet with four modern ElectroMax Overband Magnets that have been designed and built by Bunting-Redditch. The ElectroMax Overband Magnets are a major improvement over the previous model, providing…

Read MoreNew Food Sector Distributor in Turkey

Bunting has appointed Empathy as their Turkish distributor for magnetic separators, metal detectors, and X-Ray inspection systems in the food sector. Empathy joins Bunting’s growing international distributor network. Istanbul-based Empathy represents international companies in the food processing and packaging industry. The company provides complete processing and packaging solutions for food and beverage producers. Turkey is…

Read MoreMetal In Food Alerts 2022

In 2022, the UK Food Standards Agency issued ten (10) alerts regarding metal-contaminated food products that had reached the public. This was up from five (5) in 2021. The metal-contaminated food products were supplied by companies at various stages in the food supply chain, including leading UK supermarkets such as Tesco and Co-Op, as well…

Read MoreRecord-Breaking Year for Bunting-Redditch

Bunting-Redditch registered a record-breaking sales output in 2022. Despite the global economic challenges, the demand for Bunting’s metal separation equipment has never been higher. Equipment sales to companies in the recycling, plastics, mining, and mineral processing sectors drove sales growth in the year. “The extension to our premises [in 2020-2021] has enabled us to make…

Read More